- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Říj . 01, 2024 08:21 Back to list

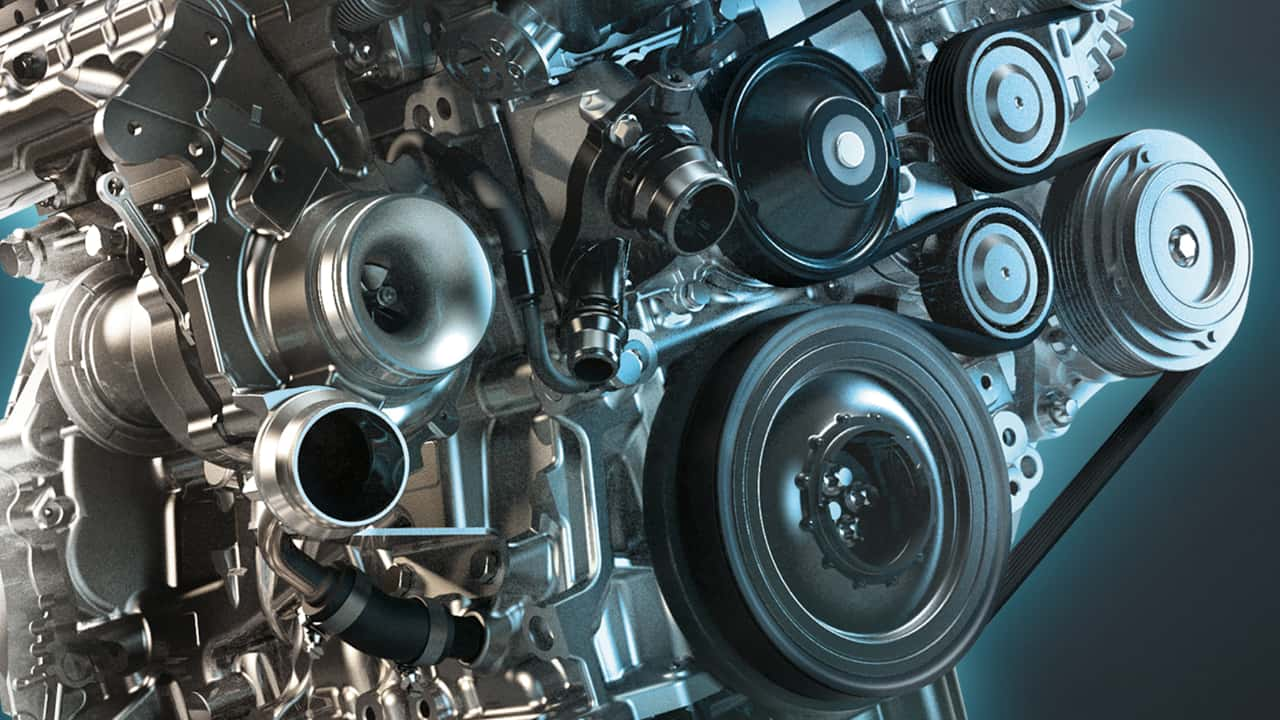

High-Performance 8PK Ribbed Belts for Enhanced Engine Efficiency and Durability

Understanding 8PK Ribbed Belts A Comprehensive Guide

In the realm of mechanical engineering and automotive applications, the importance of belts cannot be overstated. Among the various types available, the 8PK ribbed belt stands out due to its unique design and functionality. This article aims to delve into what 8PK ribbed belts are, their applications, advantages, and maintenance tips.

What is an 8PK Ribbed Belt?

An 8PK ribbed belt is a type of multi-ribbed or serpentine belt that features eight ribs along its length. The 8PK designation indicates the number of ribs and a specific profile that allows for effective transmission of power between rotating shafts. Ribbed belts are known for their flexibility and strength, making them ideal for various applications, especially in vehicles.

These belts are constructed from high-quality rubber composites, ensuring durability and resistance to wear and tear. Unlike traditional flat belts, ribbed belts grip the pulleys more effectively, reducing slippage and enhancing the efficiency of power transfer. Typically, an 8PK belt is used in scenarios where high torque is needed, as they can handle significant tension without stretching or breaking.

Applications

8PK ribbed belts are predominantly used in automotive engines but are also found in machinery that requires reliable power transmission. Some common applications include

1. Automobiles In vehicles, ribbed belts drive various components, such as the alternator, water pump, and air conditioning compressor. The 8PK belt's design allows it to handle the complex power requirements of modern engines.

2. Industrial Machinery Many industrial machines employ 8PK ribbed belts to ensure consistent operation. Their durability and strength make them suitable for heavy-duty applications, such as conveyor systems and pumps.

3. Agricultural Equipment In farming machinery, ribbed belts are integral for powering equipment like tractors and harvesters. Their ability to perform under intense conditions is a major reason for their widespread use in agriculture.

Advantages of 8PK Ribbed Belts

The 8PK ribbed belt offers several advantages over traditional belts

8pk vribbed belts

1. Enhanced Efficiency The ribbed design provides a larger surface area for contact with the pulley, minimizing slippage and maximizing power transfer.

2. Longer Lifespan Constructed from robust materials, 8PK ribbed belts are resistant to fatigue, abrasion, and environmental factors, leading to a longer operational life.

3. Reduced Noise Due to their superior grip and smoother operation, these belts tend to generate less noise compared to other belt types, contributing to a quieter work environment.

4. Easy Installation and Maintenance The design of ribbed belts allows for straightforward installation and replacement. Moreover, maintenance is simplified, as regular visual checks can ensure optimal performance.

Maintenance Tips

To extend the life of your 8PK ribbed belt, consider the following maintenance tips

1. Regular Inspection Check the belt for signs of wear, such as cracks, fraying, or discoloration. Early detection of problems can prevent catastrophic failures.

2. Correct Tension Ensure that the belt is correctly tensioned. A belt that is too tight can cause unnecessary wear on pulleys, while a loose belt may slip, leading to performance issues.

3. Clean Pulleys Dirt and debris on pulleys can affect the belt's performance. Keep pulleys clean to ensure optimal friction and power transfer.

4. Follow Manufacturer Recommendations Adhere to the manufacturer's guidelines regarding replacement intervals and installation procedures to maintain efficiency and safety.

Conclusion

The 8PK ribbed belt is a vital component in many mechanical systems, particularly in the automotive and industrial sectors. Its robust design and efficient performance make it an excellent choice for tasks requiring reliable power transmission. By understanding its applications, advantages, and maintenance needs, engineers and technicians can ensure the longevity and effectiveness of this critical component. As technology continues to evolve, the role of the 8PK ribbed belt will likely become even more significant, underscoring the importance of this seemingly simple but essential mechanical part.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025