- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 05, 2024 06:00 Back to list

belt flat

Understanding Belt Flat A Comprehensive Overview

Belt flat, a term that may not immediately ring a bell for many, is a concept that plays a vital role in various fields, from fashion to engineering and logistics. In this article, we will explore what belt flat means, its applications, and why it matters in today's world.

Definition and Context

At its core, a belt flat refers to the flat configuration or presentation of a belt, often used to facilitate storage, transportation, or display. In the fashion industry, for example, belts are often showcased in a flat manner when they are not being worn, either to maintain their shape or for aesthetic appeal in retail contexts. Similarly, in logistics and manufacturing, organizations may adopt a belt flat design for equipment to enhance space efficiency and streamline operations.

Applications in Fashion

In fashion, the belt flat is crucial for maintaining the integrity and style of the accessory. When belts are stored flat rather than hung or coiled, they are less likely to lose their shape, develop creases, or suffer from damage. Retailers often display belts in a flat format to allow customers to view their entire range without obstructions. This flat presentation can enhance visual marketing, drawing attention to the details of the product, such as the buckle design, material quality, and color.

Additionally, belt flat design is not limited to the display; many modern belt manufacturers create belts specifically designed to be flat

. This design choice leads to belts that are lightweight, versatile, and easy to pack, appealing to travelers and minimalists alike.Industrial Applications

belt flat

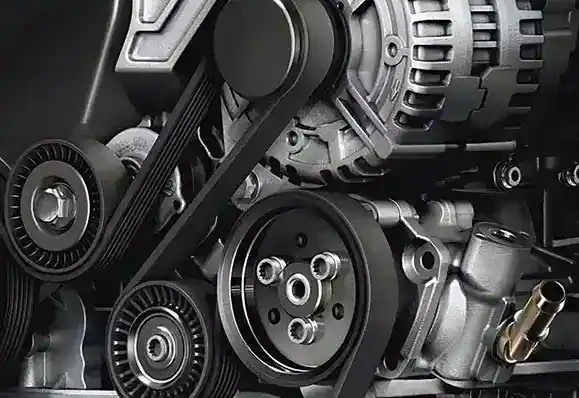

Beyond the fashion realm, the concept of a belt flat has significant implications in industrial and manufacturing contexts. For instance, conveyor belts, often used in assembly lines, can be designed to operate in a flat manner. This flat configuration allows for the efficient movement of goods and products, reducing the need for additional equipment and maximizing workflow.

Additionally, the flat design of belts in machinery can minimize wear and tear, as well as reduce energy consumption. Innovations in materials and engineering have led to the development of flat belts that offer superior performance, reduced friction, and enhanced durability. This is particularly important in industries that require precision and reliability, such as automotive manufacturing and food processing.

Benefits of the Belt Flat Configuration

The advantages of adopting a belt flat approach are manifold. In fashion, it helps in prolonging the lifespan of an accessory, ensuring it remains in pristine condition for longer. For businesses, efficient storage and display methods can lead to increased sales and improved customer satisfaction.

From an industrial perspective, flat belts contribute to more efficient operating procedures, which can lead to significant cost savings. When machinery runs smoother with less friction, it translates to lower energy costs and reduced maintenance requirements.

Conclusion

In summary, belt flat encompasses a variety of applications across different industries, highlighting its relevance in both fashion and industrial environments. Whether it's preserving the aesthetics of a stylish accessory or optimizing the operations of a manufacturing plant, the flat configuration of belts proves to be an innovative solution. As we continue to explore ways to improve efficiency and style, understanding the significance of belt flat can pave the way for new developments and opportunities in numerous sectors. Thus, embracing this concept is not just beneficial; it is essential for those looking to thrive in a competitive marketplace.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025