- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 19, 2024 00:34 Back to list

Exploring the Mechanics and Applications of Belt Drive Systems in Engineering

Belt Drive An Essential Mechanism in Mechanical Engineering

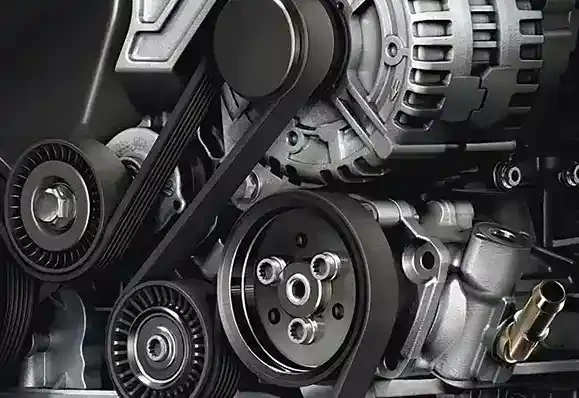

In the realm of mechanical engineering, belt drive systems have established themselves as an essential mechanism for transmitting power between components within various types of machinery. These systems are widely utilized in numerous applications, from industrial machinery and vehicles to household appliances. The design and functionality of belt drives are pivotal in ensuring efficient operation, longevity, and effective power transfer.

What is a Belt Drive?

A belt drive is a method of transmitting power using a looped and flexible material, typically referred to as a belt. The belt runs over pulleys attached to different mechanical components, thereby converting rotational motion from one shaft to another. The most common types of belts are flat belts, V-belts, and timing belts, each serving unique purposes based on their design, flexibility, and material characteristics.

Types of Belt Drives

1. Flat Belts These consist of a simple flat surface and are commonly used in older machinery. They are efficient for transmitting power over longer distances but can slip if not properly tensioned. Flat belts are typically made from leather, rubber, or synthetic materials.

2. V-Belts These belts have a trapezoidal shape that fits into matching grooves on the pulleys. This design enhances grip and reduces slippage, allowing for improved power transmission in tighter spaces. V-belts are widely used in modern equipment, including automotive engines and agricultural machinery.

3. Timing Belts Characterized by evenly spaced teeth, timing belts provide precise synchronous motion between gears. This makes them ideal for applications that require accurate timing, such as in camshaft and crankshaft systems in engines. Timing belts are often made of reinforced rubber for durability.

Advantages of Belt Drives

Belt drives offer numerous advantages that make them a preferred choice in many applications

- Cost-Effective Belt systems are generally less expensive to manufacture and install compared to other power transmission mechanisms, such as chain drives or gear systems.

- Simplicity and Flexibility The design of belt drives is relatively simple, requiring fewer components, which makes maintenance easier. Additionally, they can accommodate misalignment between shafts with minimal impact on performance.

belt drive

- Noise Reduction Compared to chain or gear systems, belt drives tend to operate more quietly, which is beneficial in settings where noise reduction is desired.

- Shock Absorption The flexibility of belts helps absorb shocks and vibrations, protecting components from wear and extending their lifespan.

Disadvantages of Belt Drives

Despite their many advantages, belt drives also have limitations

- Slippage Under heavy loads or poor tensioning, belts can slip, leading to inefficiencies and potential system failure.

- Wear and Tear Belts are subject to wear over time, necessitating regular inspections and maintenance to ensure optimal performance.

- Temperature Sensitivity Depending on the material used, belts may degrade under extreme temperatures, affecting their functionality.

Applications of Belt Drives

Belt drive systems find applications in an extensive range of industries. In manufacturing, they drive conveyor systems, machinery, and fans. In the automotive industry, they play a crucial role in engine components, such as alternators and water pumps. Household appliances, such as washing machines and vacuum cleaners, also utilize belt drives for efficient operation.

Conclusion

In conclusion, belt drives remain a fundamental aspect of mechanical engineering, combining cost-effectiveness, flexibility, and efficient power transmission. They play a critical role in various applications across multiple industries. Understanding the principles of belt drives, their types, advantages, and limitations can help engineers make informed decisions when designing systems that require reliable and efficient power transfer. As technology advances, belt drive systems continue to evolve, enabling even greater efficiency and performance in modern machinery.

-

High Performance Variable Belt Drive for Precise Timing Control

NewsJul.27,2025

-

Buy Serpentine Belt Online – Affordable Prices & Durable Quality

NewsJul.26,2025

-

High-Performance Metric Variable Speed Belts for Industrial Use

NewsJul.25,2025

-

High-Quality Endless Flat Drive Belt for Precision Power Transmission

NewsJul.24,2025

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025

-

High Efficiency V Belt Drive with Double & Toothed Options for Industry

NewsJul.22,2025