- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 13, 2024 13:50 Back to list

synchronous belt for sale

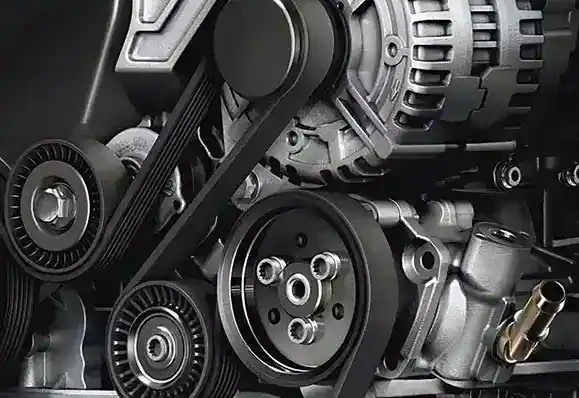

Exploring the Market for Synchronous Belts Key Considerations and Options for Sale

Synchronous belts, also known as timing belts, are integral components in the machinery and automotive industries. Their unique design and functionality make them essential for transferring rotational motion and power with precision and efficiency. With the increasing demand for high-performance and durable components in various sectors, the market for synchronous belts is thriving. This article delves into the factors influencing the sale of synchronous belts, the different types available, and important considerations for buyers.

Understanding Synchronous Belts

Synchronous belts operate based on the principle of teeth that fit precisely into matching grooves on pulleys, ensuring that there is minimal slip between the belt and the driven component. This design contributes to their efficiency, making them a preferred choice over conventional v-belts in applications where synchronous motion and precise timing are crucial.

One of the primary applications of synchronous belts is in automotive engines, where they control the timing of the crankshaft and camshaft. They are also prevalent in industrial machinery, robotics, and conveyor systems, where accurate movement and reliability are needed. As industries evolve and automation becomes more widespread, the demand for high-quality synchronous belts continues to grow.

Market Overview Types of Synchronous Belts for Sale

Synchronous belts come in various types and materials, catering to different applications and performance requirements. Some common types include

1. Neoprene Synchronous Belts These belts are known for their flexibility and resistance to wear and tear. They are commonly used in medium-duty applications and are a popular choice due to their cost-effectiveness.

2. Polyurethane Synchronous Belts With superior strength and durability, polyurethane belts are ideal for high-load applications. They are resistant to oil, chemicals, and temperature extremes, making them suitable for harsh environments.

3. Multi-Stage Synchronous Belts These specialized belts are designed for applications that require high-speed operation and precise control. They are often found in advanced machinery and production lines.

4. High-Temperature Synchronous Belts For industries that operate under extreme temperature conditions, these belts are crafted to maintain performance and reliability while resisting high heat.

synchronous belt for sale

5. Custom Synchronous Belts Many manufacturers offer the option for custom-made belts tailored to specific applications. Such products are designed based on unique requirements concerning length, width, and tooth profile.

Considerations When Purchasing Synchronous Belts

When shopping for synchronous belts, it is essential to consider several factors to ensure you select the right product for your specific needs

1. Application Requirements Analyze the intended use of the belt. Factors like load capacity, speed, and environmental conditions must be taken into account to ensure optimal performance.

2. Material Selection Choose the appropriate material based on the operational environment and specific application requirements. Materials vary in durability, flexibility, and resistance to chemicals and heat.

3. Sizing and Compatibility Ensure that the belt size matches your equipment specifications. Accurate sizing is crucial for maintaining tension and ensuring proper fit, which, in turn, affects the overall performance of the machinery.

4. Supplier Reliability Partner with reputable suppliers who offer high-quality products backed by warranties. Customer reviews and industry reputation can provide insight into the reliability and longevity of the belts.

5. Cost vs. Value While it is tempting to opt for the cheapest option, consider the long-term value. Investing in a high-quality synchronous belt can lead to reduced maintenance costs and better performance over time.

Conclusion

The market for synchronous belts is diverse and growing, driven by advances in technology and increasing industrial automation. As you explore options for synchronous belts for sale, it's crucial to consider application needs, material properties, and supplier reliability. With the right choices, you can significantly enhance the efficiency and longevity of your machinery, ensuring smooth and reliable operation in whatever application you are pursuing. Whether you're in manufacturing, automotive, or any other industry, investing in quality synchronous belts is an investment in the future of your operations.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025