- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dis . 13, 2024 15:29 Back to list

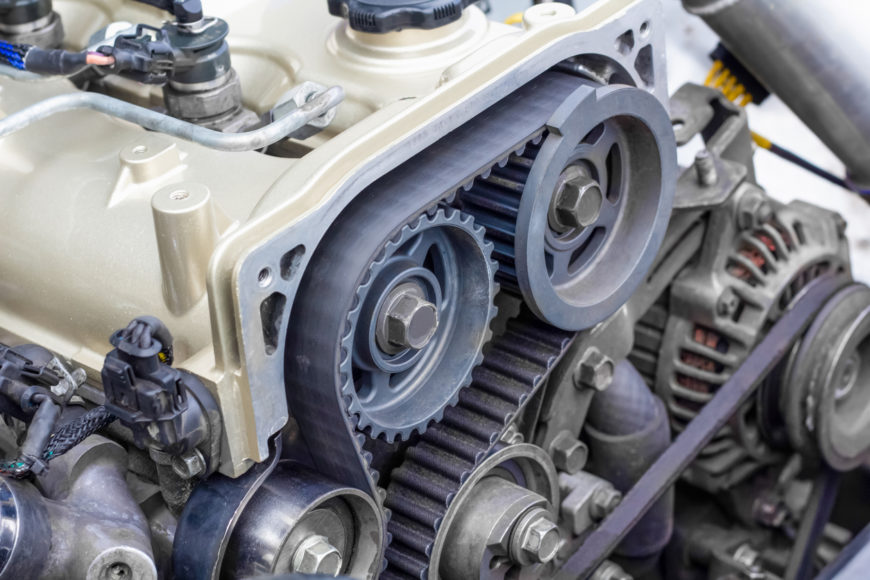

ribbed conveyor belt

The Versatility and Importance of Ribbed Conveyor Belts

Conveyor belts are essential components in many industrial and manufacturing processes. Among the various types of conveyor belts, ribbed conveyor belts have garnered significant attention due to their unique design and functionality. This article delves into the characteristics, advantages, applications, and maintenance considerations surrounding ribbed conveyor belts.

Characteristics of Ribbed Conveyor Belts

Ribbed conveyor belts, also known as profile or patterned belts, are distinguished by their raised edges or ribs that run parallel to the length of the belt. These ribs are designed to enhance the belt's traction and facilitate the transport of materials at an incline. Typically made from durable materials such as rubber, PVC, or polyurethane, ribbed conveyor belts are engineered to withstand heavy loads, resist wear and tear, and endure varying environmental conditions.

The ribbed design creates pockets within the belt, allowing it to securely hold products, particularly when moving them upwards or at angles. This feature minimizes the risk of slippage or product fall-off, making ribbed belts particularly valuable in settings where safety and efficiency are paramount.

Advantages of Ribbed Conveyor Belts

One of the most significant advantages of ribbed conveyor belts is their ability to move materials at steep angles—up to 30 degrees or more—without compromising performance. This capability is essential in industries such as mining, agriculture, and bulk material handling, where space is limited, and vertical transport is crucial.

Additionally, ribbed conveyor belts provide enhanced grip, reducing the likelihood of material slipping backward. This ensures consistent and reliable material flow, which is vital for maintaining production schedules and minimizing downtime.

Another critical benefit is the customization options available for ribbed conveyor belts

. Businesses can tailor the rib height, spacing, and overall design to fit specific material types and sizes, enhancing operational efficiency. This adaptability makes ribbed conveyor belts suitable for various industries, from food processing to warehousing.ribbed conveyor belt

Applications of Ribbed Conveyor Belts

Ribbed conveyor belts find applications in a plethora of industries. In the food and beverage sector, they are commonly used to transport items like packaged goods, fruits, and vegetables. The ribbed surface prevents delicate products from slipping and ensures smooth transition between processing stages.

In agriculture, ribbed conveyor belts are employed to move grain, seeds, and other bulk materials efficiently. Their ability to transport materials at an angle helps maximize space within storage facilities and processing plants.

Similarly, in logistics and warehousing, ribbed belts are ideal for sorting and distributing products along conveyor systems. Their design allows for quick and efficient movement of goods, contributing to streamlined operations.

Maintenance Considerations

Maintaining ribbed conveyor belts is crucial to ensuring their longevity and optimal performance. Regular inspections for signs of wear, such as rib deterioration or belt misalignment, should be conducted. Keeping the belt clean and free from debris is essential to prevent unnecessary friction and potential damage.

Additionally, proper tensioning is important. A belt that is too loose may slip, while a belt that is too tight can cause excessive wear on the drive components. Adjustments should be made according to the manufacturer's specifications and the specific requirements of the application.

Conclusion

Ribbed conveyor belts play a pivotal role in enhancing material handling processes across various industries. Their unique design provides significant advantages, including increased traction, customization options, and adaptability to challenging transport scenarios. As industries continue to evolve, the importance of reliable and efficient transportation systems will only grow, solidifying the role of ribbed conveyor belts as a cornerstone of modern manufacturing and logistics. Investing in quality ribbed conveyor belts and adhering to proper maintenance practices will ultimately lead to improved efficiency, safety, and productivity in any operation.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025