- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 02, 2024 12:52 Back to list

original v belt

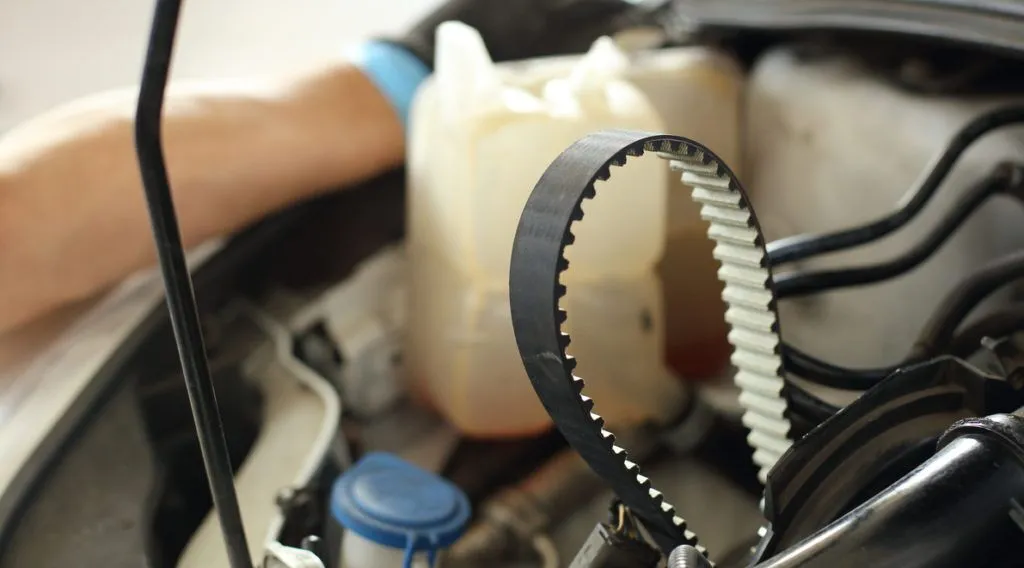

The Importance of Original V-Belts in Machinery Performance

In the realm of industrial machinery and automotive systems, the components that keep these systems running efficiently cannot be underestimated. One such crucial component is the V-belt, particularly the original V-belt, which plays a vital role in power transmission and machine operation. Understanding the significance of original V-belts is essential for anyone involved in equipment maintenance or manufacturing.

V-belts are designed to transfer power between the motor and various driven components, such as pumps, fans, and alternators. They have a trapezoidal cross-section that allows them to fit snugly into pulleys, providing a reliable grip that reduces slippage. While the concept of the V-belt is straightforward, the quality and specifications of these belts can significantly affect machine performance.

The Importance of Original V-Belts in Machinery Performance

Durability is another aspect where original V-belts shine. High-quality materials used in their production contribute to their longevity and resistance to wear and tear. Original V-belts undergo rigorous testing and quality control, which generic belts often do not. This results in a product that can withstand the demanding conditions typical in industrial environments, including high temperatures, humidity, and exposure to various chemicals.

original v belt

Furthermore, original V-belts are designed with advanced engineering considerations such as flexibility and tensile strength. The flexibility allows them to bend around pulleys without compromising their structural integrity, while their tensile strength ensures they can handle the torque generated by the engine. This combination prevents premature belt failure, which can lead to costly downtime and repairs.

In addition to performance benefits, using original V-belts contributes to overall safety. Worn or inferior belts can break or slip, posing risks not only to the machinery but also to the operators. Original V-belts are designed to minimize these risks, providing peace of mind to those who rely on these machines for their daily operations.

Finally, opting for original V-belts can enhance the lifespan of connected equipment. By ensuring that the power transmission system works optimally, users can reduce the risk of excessive stress on motors and other components, which can lead to expensive repairs or replacements down the line.

In conclusion, the choice between original and generic V-belts is significant. Original V-belts provide superior fit, durability, and performance, all of which are essential for maintaining efficient machinery operations. They reduce the likelihood of mechanical failures, enhance safety, and contribute to the longevity of the entire system. For anyone responsible for machinery upkeep or production, investing in original V-belts is not just a matter of performance; it is a fundamental aspect of operational reliability and safety.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025