- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 13, 2024 02:41 Back to list

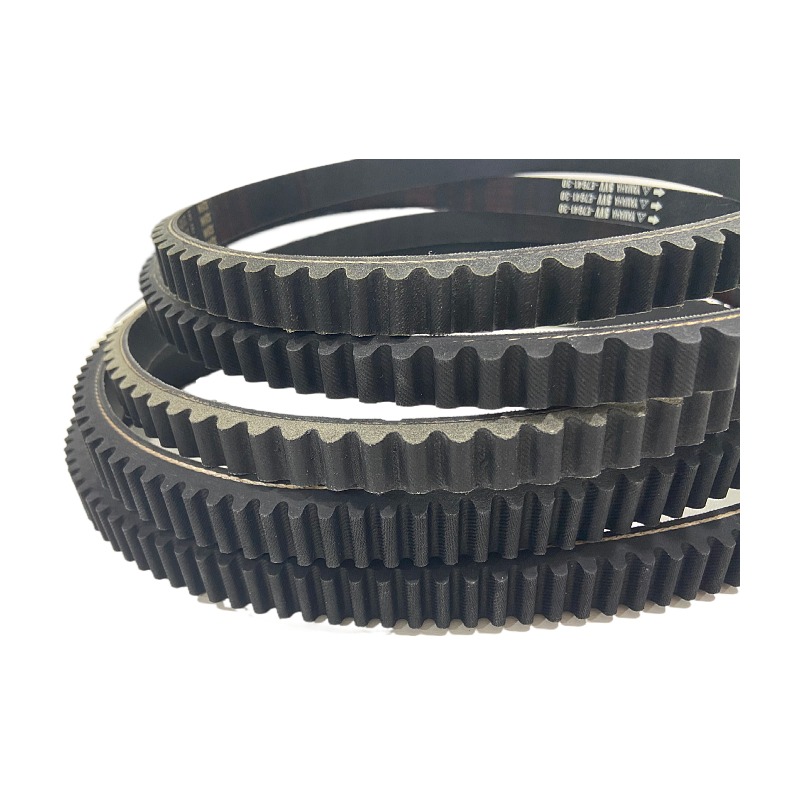

8 rib serpentine belt

Understanding 8% Rib Serpentine Belts

Serpentine belts are an essential component in modern automotive engineering, acting as the linchpin in various belt-driven accessories within vehicles. The 8% rib serpentine belt, in particular, has gained attention due to its unique design and functionalities. In this article, we will delve into what an 8% rib serpentine belt is, its advantages, applications, and maintenance tips.

What is an 8% Rib Serpentine Belt?

A serpentine belt is a long, continuous belt used in vehicles to drive multiple peripherals such as the alternator, power steering pump, water pump, and air conditioning compressor. The 8% rib designation refers to the number of ribs on the belt's surface. These ribs enhance grip and provide a more secure connection to the pulleys, facilitating efficient power transfer from the engine to various components.

The materials used in manufacturing serpentine belts have advanced significantly over the years, with options like EPDM (Ethylene Propylene Diene Monomer). This synthetic rubber formulation offers excellent resistance to wear, heat, and environmental factors, making it ideal for automotive applications. The 8% rib design allows for added flexibility and reduced stretching over time, ensuring a longer lifespan.

Advantages of the 8% Rib Design

The 8% rib serpentine belt offers several advantages over traditional flat belts and those with fewer ribs. Firstly, the increased surface area provided by the ribs enhances traction on the pulleys, which translates into improved performance. This reduces slippage, increasing the efficiency of accessory components, leading to better fuel economy and engine performance.

8 rib serpentine belt

Additionally, this design minimizes noise during operation. The ribs allow for a smoother engagement with the pulleys, decreasing vibration and creating a quieter engine bay environment. Furthermore, the ribbed design helps in aligning the belt correctly, reducing wear due to misalignment, which is a common issue with flat belts.

Applications

8% rib serpentine belts are widely used in various vehicles, including passenger cars, trucks, and SUVs. Their ability to drive multiple accessory systems makes them a versatile choice for automakers. Beyond automotive use, these belts also find applications in other industries, such as manufacturing and machinery, where reliable power transmission is critical.

Maintenance Tips

Maintaining your serpentine belt is vital for ensuring your vehicle runs smoothly. Regular inspections should be performed to check for signs of wear such as cracks, fraying, or glazing. It's also essential to listen for unusual noises while the engine is running, as this could indicate slippage or misalignment. If any issues are detected, it's advisable to replace the serpentine belt promptly to prevent damage to the engine or other components.

In conclusion, the 8% rib serpentine belt plays a crucial role in the efficiency and performance of modern vehicles. With its superior grip, durability, and reduced noise levels, it has become a preferred choice among manufacturers and vehicle owners alike. Regular maintenance and timely replacements will ensure this important component continues to operate effectively, contributing to the longevity and reliability of your vehicle.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025