- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

nov . 15, 2024 12:23 Back to list

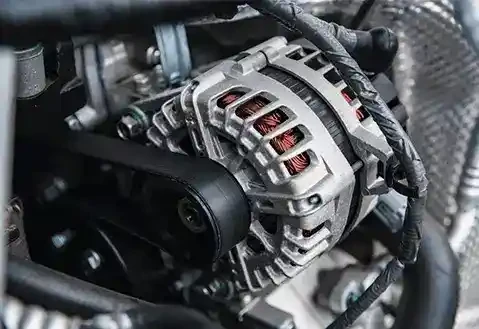

transmission belt

Understanding Transmission Belts An Essential Component in Mechanical Engineering

Transmission belts are a crucial element in various mechanical systems, providing a reliable means of transferring power between components. These belts play a vital role in machinery, automotive systems, and countless other applications, ensuring that energy is transmitted efficiently and effectively. Their design and functionality are fundamental in both small and large-scale mechanical setups.

What Are Transmission Belts?

A transmission belt is a looped strip of flexible material that transmits power from one pulley to another. The primary function of a transmission belt is to transfer rotational motion and torque between shafts without the need for gears or other complex mechanisms. Transmission belts are typically made from rubber or synthetic materials, providing the necessary durability and flexibility to withstand repeated use.

Types of Transmission Belts

There are several types of transmission belts, each designed for specific applications and conditions. The most common types include

1. V-Belts These are wedge-shaped belts that fit into the grooves of pulleys. Their design allows for better grip and efficient power transfer, making them popular in machinery like conveyors and compressors.

2. Flat Belts As the name suggests, flat belts have a simple design and are used in applications where high speed is required. They are often found in older machines and are effective in transferring power over long distances.

3. Timing Belts These belts have teeth or grooves that fit into corresponding pulleys, ensuring precise synchronization between the engine components. They are commonly used in automotive engines, where accurate timing is crucial for performance.

transmission belt

4. Toothed Belts Similar to timing belts, toothed belts feature teeth that engage with pulleys for a secure fit. They are often used in high-torque applications and offer low maintenance and high efficiency.

Applications of Transmission Belts

Transmission belts are used in a wide range of applications across various industries. In automotive engineering, timing belts and serpentine belts are vital for the operation of engines. They help to synchronize the movement of the crankshaft and camshaft, ensuring that engine valves open and close at the correct times.

In manufacturing, conveyor belts, which can also be classified as transmission belts, are instrumental in moving products along assembly lines. Their efficiency in transporting goods makes them indispensable in industries such as food processing, packaging, and materials handling.

Additionally, transmission belts are present in household appliances like washing machines and lawnmowers, where they assist in the smooth operation of motors and other mechanical components.

Maintenance and Durability

To ensure longevity and optimal performance, transmission belts require regular maintenance. Factors like wear and tear, environmental conditions, and misalignment can all impact their lifespan. Regular inspections are essential to detect signs of wear, such as fraying or cracking. Proper alignment and tensioning are equally important; improperly tensioned belts can lead to slippage, reduced efficiency, and premature failure.

Conclusion

Transmission belts are an integral part of modern mechanical systems, essential for the efficient transfer of power. With various types designed for specific applications, they contribute significantly to the functionality of machines in numerous industries, from automotive to manufacturing. Understanding the types, applications, and maintenance of transmission belts is crucial for ensuring that systems operate smoothly and effectively. As technology continues to evolve, the development of new materials and designs for transmission belts promises to enhance their performance and durability further, solidifying their role in the future of mechanical engineering.

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025

-

High-Performance Variable Speed V Belt Drive for Efficient Power Transmission

NewsJul.30,2025