- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jan . 31, 2025 03:36 Back to list

timing belt and timing chain

In the dynamic world of manufacturing, the production line for timing belts stands as a testament to precision, efficiency, and innovation. A hub of technological advancement, these production lines blend cutting-edge machinery with stringent quality controls to produce components that are vital for the automotive, industrial, and consumer sectors. This article delves into the intricate processes and expertise that define a successful timing belt production line, providing insights from industry veterans to underline its critical role in modern manufacturing.

Following molding, the belts advance to the curing stage, where they are treated with heat to achieve their final physical properties. Curing ovens are calibrated to exact specifications, a process closely monitored by seasoned technicians who bring a wealth of experience to the table. This attention to detail ensures that each belt emerges with the appropriate hardness and elasticity, ready to be deployed in precision-driven applications where failure is not an option. Finally, the belts undergo stringent quality control procedures. In this critical stage, each belt is scrutinized for defects, tensile strength, and dimensional accuracy. Utilizing both manual inspections and sophisticated testing equipment, this phase epitomizes the authoritativeness and trustworthiness embedded in production line protocols. Products are certified only after meeting rigorous internal and external standards, instilling confidence in end-users across various industries. In conclusion, the production of timing belts is a sophisticated endeavor that marries advanced technology with human expertise. It is this blend of experience, professionalism, and unwavering dedication to quality that positions timing belt production lines as pivotal in the manufacturing sector. By understanding the intricacies of each step—from material selection to quality assurance—industry professionals continue to innovate and elevate standards, ensuring that timing belts effectively support the engines and machines that drive our world forward. This continuous pursuit of excellence not only fortifies the authority of manufacturers in the market, but also fosters trust among clients who rely on their products for critical applications.

Following molding, the belts advance to the curing stage, where they are treated with heat to achieve their final physical properties. Curing ovens are calibrated to exact specifications, a process closely monitored by seasoned technicians who bring a wealth of experience to the table. This attention to detail ensures that each belt emerges with the appropriate hardness and elasticity, ready to be deployed in precision-driven applications where failure is not an option. Finally, the belts undergo stringent quality control procedures. In this critical stage, each belt is scrutinized for defects, tensile strength, and dimensional accuracy. Utilizing both manual inspections and sophisticated testing equipment, this phase epitomizes the authoritativeness and trustworthiness embedded in production line protocols. Products are certified only after meeting rigorous internal and external standards, instilling confidence in end-users across various industries. In conclusion, the production of timing belts is a sophisticated endeavor that marries advanced technology with human expertise. It is this blend of experience, professionalism, and unwavering dedication to quality that positions timing belt production lines as pivotal in the manufacturing sector. By understanding the intricacies of each step—from material selection to quality assurance—industry professionals continue to innovate and elevate standards, ensuring that timing belts effectively support the engines and machines that drive our world forward. This continuous pursuit of excellence not only fortifies the authority of manufacturers in the market, but also fosters trust among clients who rely on their products for critical applications.

Share:

Next:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

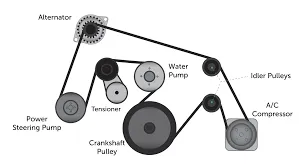

drive belt serpentine belt

NewsMar.07,2025