- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

окт. . 31, 2024 11:29 Back to list

Belt Options for Cummins Engine Performance Enhancement and Maintenance Tips

Understanding Belts for Cummins Engines Importance and Choices

Cummins engines are renowned for their durability, reliability, and efficiency, making them a popular choice in various applications, from heavy-duty trucks to power generation. One crucial component that ensures these engines operate smoothly is the drive belt, commonly referred to as the serpentine belt. This article delves into the importance of the drive belt in Cummins engines and the options available for maintenance and replacement.

The Role of the Drive Belt

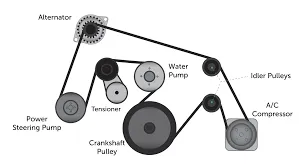

The drive belt in a Cummins engine serves multiple functions. It connects and drives several components such as the alternator, power steering pump, water pump, and air conditioning compressor. By translating the rotational power from the engine's crankshaft, the belt enables these accessories to function efficiently, ensuring optimal performance of the engine as a whole. A well-maintained drive belt helps prevent overheating, electrical issues, and steering problems, which could lead to expensive repairs or breakdowns.

Signs of Wear and Tear

Over time, drive belts can experience wear and tear due to exposure to heat, friction, and environmental factors. Common signs that your Cummins engine's drive belt may need attention include visible cracks, fraying, or glazing on the belt’s surface. Additionally, if you hear squeaking or chirping noises when the engine is running, it could indicate that the belt is slipping or has become loose. Regular inspections can help catch these issues early, which is crucial for maintaining the engine’s overall health.

Choosing the Right Belt

for cummins engine belt

When it comes to selecting a replacement belt for a Cummins engine, it's essential to choose a high-quality product that meets the manufacturer's specifications. Aftermarket options are available, but it's crucial to select those that have been tested for durability and compatibility with Cummins engines. Brands that specialize in heavy-duty parts often provide belts that are designed specifically for the rigorous demands of Cummins engines.

Maintenance Tips

To extend the life of your drive belt, consider implementing the following maintenance tips

1. Regular Inspection Check the drive belt every few months for signs of wear or damage. 2. Proper Tension Ensure the belt is appropriately tensioned. A loose belt can slip, while a tight belt can cause premature wear on the pulleys. 3. Replace When Necessary Follow the manufacturer's recommendations for replacement intervals, but also use your judgment based on the belt's condition.

Conclusion

The drive belt is a vital component of Cummins engines, directly affecting their performance and longevity. By understanding its importance and knowing when to replace it, you can help ensure that your engine operates efficiently for years to come. Whether through routine maintenance or choosing the right replacement parts, taking care of your Cummins engine's drive belt is essential for optimal performance.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025