- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

авг. . 08, 2025 02:40 Back to list

Durable Tooth Belts: Precision Power for Poly V Belt Drives

In the dynamic landscape of industrial machinery and power transmission, the efficiency and reliability of components are paramount. At the heart of many high-performance systems lies the often-underestimated, yet critically important, tooth belt. This article delves into the intricate world of tooth belt technology, exploring its evolution, technical prowess, diverse applications, and the strategic advantages it offers across various industries. We will also highlight how advanced manufacturing, exemplified by products like the China Classical V-Belt Manufacturer 21x14-1650, is setting new benchmarks for performance and durability in power transmission.

The Evolving Landscape of Power Transmission: Focus on Tooth Belt Technology

The industrial sector is constantly striving for higher efficiency, reduced maintenance, and enhanced operational longevity. Traditional belt drives, while foundational, are increasingly being replaced or complemented by sophisticated solutions like the tooth belt. Also known as synchronous belts, timing belts, or toothed belts, these components offer precise power transmission without slippage, making them indispensable in applications requiring exact synchronization, such as robotics, CNC machines, and printing presses. The growth in automation and precision manufacturing is a significant driver for the adoption of advanced tooth belt systems.

Beyond precision, modern industrial demands lean heavily towards energy efficiency and environmental sustainability. Tooth belt drives inherently offer higher mechanical efficiency compared to V-belts or chain drives due to minimal friction and no slippage. This directly translates to reduced energy consumption and lower operational costs, aligning perfectly with global industrial trends towards greener technologies and optimized resource utilization. The industry is witnessing a shift towards composite materials and advanced manufacturing techniques that further enhance belt strength, flexibility, and resistance to harsh operating conditions.

Understanding the Core: Technical Parameters of Tooth Belt

A tooth belt's performance is defined by several critical technical parameters. Understanding these is crucial for selecting the right belt for a specific application, ensuring optimal power transmission and longevity. Key parameters include:

- Pitch (P): The distance between the centers of two adjacent teeth. Common pitches include XL, L, H, HTD (High Torque Drive) profiles like 3M, 5M, 8M, 14M, and GT (General Transmission) profiles.

- Tooth Profile: Refers to the shape of the teeth (e.g., trapezoidal, curvilinear, modified curvilinear). The profile significantly influences engagement, load distribution, and noise levels. HTD profiles, for instance, offer better load distribution and reduced stress concentrations than trapezoidal profiles.

- Belt Width (W): The measurement across the belt's top surface. Wider belts can transmit more power.

- Number of Teeth (N) / Pitch Length (Lp): The total number of teeth or the total length of the belt along its pitch line.

- Material Composition: Typically a combination of a robust rubber compound (Neoprene, EPDM, HNBR), high-strength tension members (fiberglass, steel, Kevlar, carbon fiber), and a fabric facing on the teeth (nylon) for wear resistance.

- Tensile Strength: The maximum stress the belt can withstand before breaking, primarily determined by the tension member material.

- Operating Temperature Range: The range of temperatures within which the belt can operate effectively without degradation.

- Static Conductivity: For applications where static electricity buildup is a concern, belts may be designed to be static conductive.

Typical Tooth Belt Parameter Overview

Below is a general table showcasing common parameters found in various tooth belt types. These values vary significantly based on specific designs and applications, but they provide a baseline for understanding:

| Parameter | Common Range/Type | Description |

|---|---|---|

| Pitch Profile | HTD (3M, 5M, 8M, 14M), STD (S3M, S5M, S8M), MXL, XL, L, H | Defines tooth shape and spacing for synchronous power transmission. HTD offers higher torque. |

| Belt Material | Neoprene, HNBR Rubber, Polyurethane | Elastomer base for flexibility and durability. HNBR for oil/heat resistance. Polyurethane for precision. |

| Tension Member | Fiberglass, Steel, Aramid (Kevlar), Carbon Fiber | Reinforcement cords providing strength and dimensional stability. |

| Tooth Facing | Nylon Fabric | Protects teeth from wear and reduces friction. |

| Operating Temp. | -30°C to +100°C (Neoprene) / -40°C to +120°C (HNBR) | Temperature range for optimal performance and longevity. |

| Max. Linear Speed | Up to 80 m/s (approx. 15,750 ft/min) | Maximum safe speed for the belt without excessive vibration or heat buildup. |

| Efficiency | Up to 98-99% | High power transmission efficiency due to positive engagement. |

| Noise Level | Low (especially with curvilinear profiles) | Generally quieter than chain drives; varies with profile and tension. |

| Maintenance | Low, no lubrication required | Reduces downtime and operational costs. |

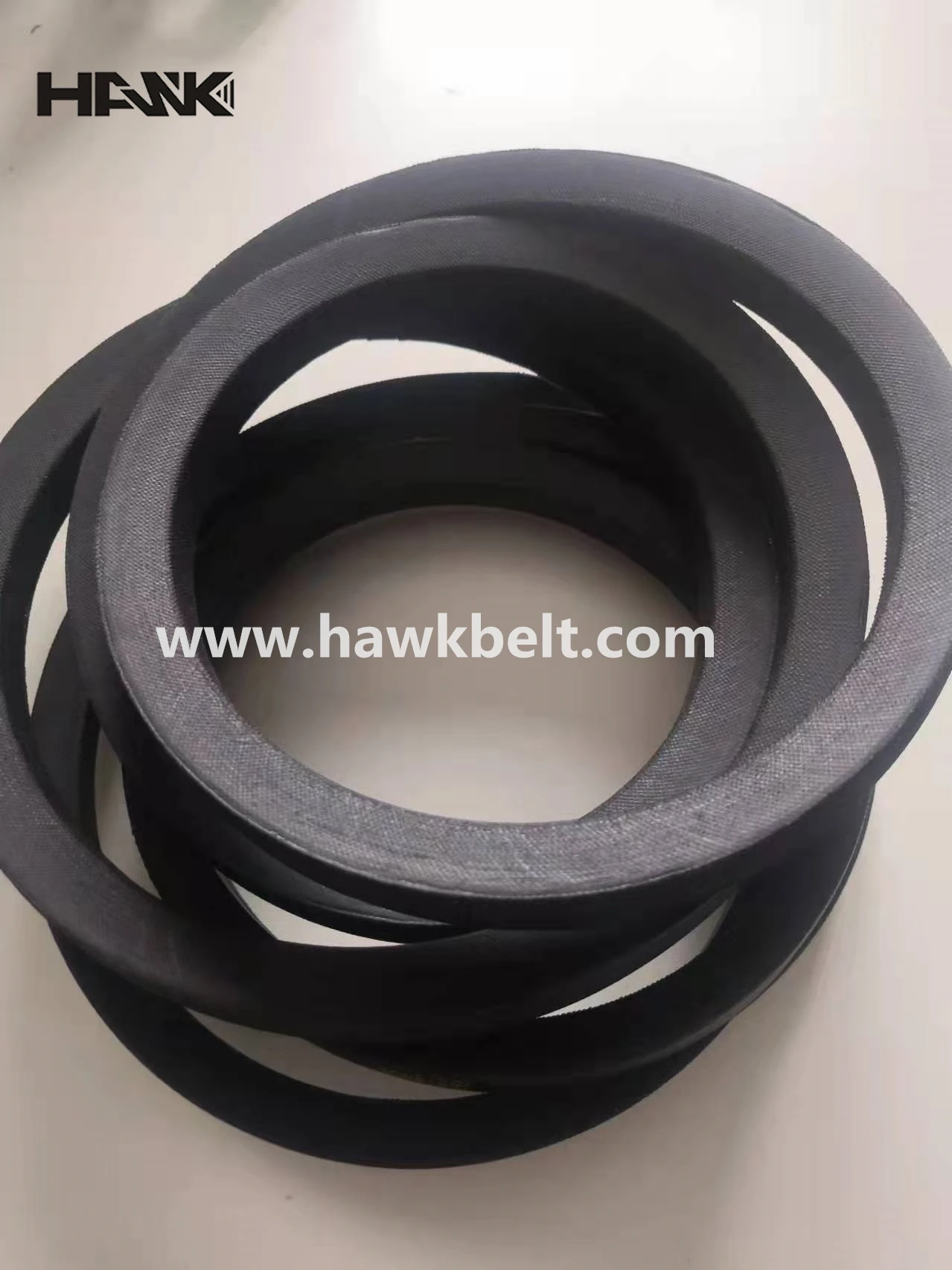

Figure 1: A typical tooth belt application showcasing its critical role in synchronized power transmission within industrial machinery.

Application Scenarios: Where Tooth Belt Excels

The versatility and performance of tooth belt technology allow it to be deployed across an incredibly diverse range of industries and applications. Its ability to provide precise timing and high efficiency makes it a preferred choice over other transmission methods in many demanding environments.

- Automotive Industry: Widely used as timing belts in internal combustion engines, synchronizing crankshaft and camshaft rotation. Also found in power steering and auxiliary drives.

- Manufacturing and Automation: Essential in robotic systems, CNC machines, conveyors, and automated assembly lines where precise positioning and movement synchronization are critical.

- Textile Industry: Driving looms, spinning machines, and printing equipment that require consistent and accurate speed.

- Printing and Paper Industry: Used in high-speed printing presses for precise paper feeding and print registration, and in paper converting machinery.

- Food Processing: In applications where cleanliness and non-lubricated operation are key, tooth belts, especially those with specialized coatings, are used for conveyors and processing equipment.

- HVAC Systems: For driving fans and compressors in large air handling units, where quiet operation and energy efficiency are beneficial.

- Packaging Industry: Precise indexing and positioning of products on packaging lines.

- Medical Equipment: In some precise diagnostic or analytical equipment where smooth, accurate motion is required.

- Mining and Aggregate: Though less common than heavy-duty conveyor belts, specialized reinforced tooth belts can be used in certain crushing and screening applications.

Figure 2: An example of a poly v ribbed belt, showcasing the ribbed structure designed for high power transmission and flexibility.

Technical Advantages: Why Choose Advanced Tooth Belt Solutions?

The shift towards sophisticated tooth belt systems, including specialized variants like the poly v ribbed belt or the poly v belt drive, is driven by their superior technical advantages over traditional V-belts or chain drives.

- High Efficiency: With efficiency ratings often exceeding 98%, tooth belts minimize energy loss due to their positive engagement with sprockets, eliminating slippage. This directly contributes to significant energy savings over the lifespan of the machinery.

- Precision and Synchronization: Unlike friction-dependent belts, tooth belts ensure exact speed ratios and angular positioning. This makes them ideal for applications requiring precise timing and accurate synchronization, such as robotics and printing.

- Low Maintenance & No Lubrication: Tooth belts do not require lubrication, which eliminates messy oil baths or grease application. This reduces maintenance time, costs, and prevents contamination, particularly beneficial in food processing or cleanroom environments.

- Reduced Noise Levels: The smooth meshing of teeth, especially with advanced tooth profiles, results in significantly quieter operation compared to noisy chain drives or squealing V-belts.

- Compact Design: Tooth belts can often transmit more power in a smaller footprint than other drive types, allowing for more compact machine designs.

- Clean Operation: No lubrication means no oil fling or particulate generation, making them suitable for environments where cleanliness is critical, such as electronics manufacturing or medical device production.

- Long Service Life: Constructed from high-quality materials and designed for durability, modern tooth belts offer extended operational lives, reducing the frequency of replacements and associated downtime.

- Corrosion Resistance: Many modern tooth belt materials are inherently resistant to common industrial chemicals, oils, and moisture, making them suitable for harsh environments like petrochemical plants or water treatment facilities. For example, specific rubber compounds (like HNBR) offer excellent resistance to oil and high temperatures.

Product Focus: China Classical V-Belt Manufacturer 21x14-1650

Product Highlight: China Classical V-Belt Manufacturer 21x14-1650

While our primary focus is on the advanced capabilities of tooth belts, it's important to recognize the foundation of belt technology. Our product, the China Classical V-Belt Manufacturer 21x14-1650, represents a pinnacle in traditional V-belt engineering, manufactured with precision and adhering to stringent quality controls. This classical V-belt, while differing in principle from a synchronous tooth belt, shares the same commitment to material excellence, robust manufacturing, and reliable performance that our advanced synchronous belts also embody.

This 21x14-1650 V-belt is engineered for demanding power transmission in various industries where reliability and cost-effectiveness are key. Its dimensions indicate a sturdy build: 21mm top width, 14mm height, and 1650mm pitch length (or effective length). It is designed to deliver consistent power in applications such as:

- General industrial machinery (compressors, pumps, fans)

- Agricultural equipment

- HVAC systems

- Crushing and conveying systems (where a reliable, non-synchronous drive is acceptable)

Its robust construction ensures good resistance to shock loads and allows for simple installation and maintenance, making it a popular choice for many heavy-duty applications. Our commitment to quality ensures this classical V-belt delivers exceptional service life and reliability, reflecting the same high standards applied to our tooth belt range.

View Product DetailsManufacturing Process of a High-Performance Power Transmission Belt (Including Principles for Tooth Belt)

The manufacturing of high-quality power transmission belts, including both classical V-belts and advanced tooth belts, is a complex process that demands precision engineering, material science expertise, and rigorous quality control. While the specific product highlighted is a classical V-belt, the underlying principles of material selection, robust construction, and stringent testing apply universally to our high-performance synchronous tooth belts. Here's a generalized overview of the manufacturing process, emphasizing key aspects relevant to both types:

- Material Compounding and Preparation:

- Elastomer Base: High-grade synthetic rubber compounds such as Neoprene, HNBR (Hydrogenated Nitrile Butadiene Rubber), or EPDM (Ethylene Propylene Diene Monomer) are precisely blended with various additives (curatives, fillers, plasticizers, anti-degradants) to achieve specific properties like flexibility, heat resistance, oil resistance, and durability. For a poly v ribbed belt or a poly v belt, the compound needs to withstand continuous bending stresses and frictional heat.

- Tension Members (Cords): High-strength fibers like polyester, fiberglass, aramid (Kevlar), or carbon fiber are selected. These cords are precisely twisted and treated for optimal adhesion to the rubber matrix and minimal elongation. This is crucial for maintaining the pitch integrity of a tooth belt.

- Facing Fabrics: For tooth belts, a wear-resistant nylon fabric is often applied to the teeth surface to reduce friction and improve wear life. This fabric is also treated for better adhesion.

- Cord Winding/Placement:

The tension cords, pre-treated for adhesion, are precisely wound onto mandrels or specialized molds. For classical V-belts, this forms the neutral axis that carries the load. For tooth belts, the cords are strategically placed to ensure uniform tooth pitch and minimal stretch, which is vital for maintaining synchronous operation. This is a critical step for dimensional stability.

- Forming and Layering:

Different layers of rubber compound (base rubber, insulation rubber, top cover rubber), along with the tension cords and facing fabric (for tooth belts), are carefully assembled and layered onto the mandrel. For tooth belts, the tooth profile is typically formed during this stage using precisely machined molds.

- Curing (Vulcanization):

The assembled belt "blanks" are placed into large presses and subjected to high temperature and pressure. This vulcanization process chemically cross-links the rubber polymers, transforming the pliable raw materials into a durable, elastic, and heat-resistant finished product. This is where the belt gains its final shape, mechanical strength, and performance characteristics. The precise control of temperature and pressure is vital to ensure uniform cure and optimal material properties.

- Post-Curing Processing and Cutting:

After curing, the large belt sleeves (multiple belts formed on one mandrel) are removed from the molds. They are then precisely cut to the specified widths using automated cutting machines. This ensures consistent dimensions across all manufactured belts. For classical V-belts, this defines the 21x14mm cross-section of our product.

- Final Inspection and Testing:

Every belt undergoes a series of rigorous quality control checks. This includes visual inspections for defects, dimensional checks (width, height, length, pitch for tooth belts), and performance testing. Tests may include:

- Tensile Strength Testing: To ensure the belt can withstand specified loads.

- Fatigue Testing: Simulating real-world operating conditions to assess service life and durability.

- Dimensional Stability Testing: Crucial for tooth belts to guarantee pitch accuracy and prevent jumping teeth.

- Adhesion Testing: Ensuring proper bonding between different material layers.

Manufacturers adhere to international standards such as ISO (International Organization for Standardization) and ANSI (American National Standards Institute) for product specifications and testing protocols. For instance, ISO 5296 defines dimensions for synchronous belts, while ISO 1813 deals with static conductivity. Adherence to these standards guarantees reliability and interchangeability.

Highlighting Material & Manufacturing Excellence: Our China Classical V-Belt Manufacturer 21x14-1650 is a testament to this detailed process. Its specific 21x14mm profile is achieved through precise molding and curing, using high-quality synthetic rubber compounds and polyester tensile cords for durability. This ensures it delivers exceptional torque transmission and energy efficiency (for a V-belt) in demanding applications. Its robust design minimizes stretching and wear, contributing to a significantly longer service life compared to inferior alternatives.

In application scenarios such as petrochemical facilities or water treatment plants, the inherent material resistance to common industrial fluids and temperatures ensures superior performance and longevity. The manufacturing process is geared towards delivering a product that not only meets but exceeds the expectation for reliability and cost-efficiency, reducing the need for frequent replacements and thereby minimizing operational downtime.

Figure 3: A schematic representation of a poly v belt drive system, illustrating its compact design and multi-ribbed contact surface.

Manufacturer Comparison and Selection Criteria for Advanced Belt Solutions

Choosing the right manufacturer for your power transmission needs, whether it's for a standard V-belt or an advanced tooth belt or poly rib belt, is as crucial as selecting the belt itself. A reputable manufacturer contributes significantly to the reliability, efficiency, and longevity of your machinery.

Key Criteria for Manufacturer Selection:

- Expertise & Experience:

Look for manufacturers with a long history and deep understanding of belt design, material science, and application engineering. Our company, with decades of experience in the belt manufacturing industry, embodies this principle. We've been serving diverse sectors like petrochemical, metallurgy, and water treatment, accumulating invaluable experience that translates into superior product design and performance.

- Quality Control & Certifications:

Verify that the manufacturer adheres to international quality standards such as ISO 9001. This indicates a robust quality management system throughout the production process. Products should meet relevant ANSI, RMA (Rubber Manufacturers Association), or DIN standards. Our commitment to these standards ensures every belt, from the classical V-belt to advanced tooth belts, consistently meets stringent performance criteria.

- R&D and Innovation:

A leading manufacturer invests in research and development to introduce new materials, improved profiles, and innovative manufacturing techniques. This ensures they can offer cutting-edge solutions like specialized poly v ribbed belts designed for specific harsh environments or higher power density requirements.

- Customization Capabilities:

Many industrial applications require bespoke solutions. A good manufacturer should offer extensive customization options, from specific lengths and widths to unique material compositions for extreme temperature, chemical resistance, or static conductivity needs.

- Technical Support & After-Sales Service:

Availability of expert technical support for selection, installation, troubleshooting, and maintenance is vital. Prompt and efficient customer service, including clear warranty policies, enhances trustworthiness.

- Client Testimonials & Case Studies:

Real-world application examples and positive client feedback provide strong evidence of a manufacturer's reliability and product performance. We pride ourselves on long-standing relationships with major industry players, a testament to our consistent delivery of high-quality solutions and exceptional service.

Custom Solutions and Application Cases: Tailored Performance

While standard belt products cater to a wide range of needs, many specialized industrial applications demand bespoke solutions. This is where a manufacturer's ability to offer custom tooth belt designs becomes a significant advantage. Whether it’s an exceptionally long tooth belt for large conveyors or a specific poly rib belt with enhanced chemical resistance for corrosive environments, custom engineering ensures optimal performance and longevity.

Example Customization Scenarios:

- Extreme Temperature Belts: Developing belts with specialized HNBR or silicone compounds for continuous operation in temperatures from -60°C to +150°C, crucial for applications in metallurgical processing or cold storage facilities.

- Anti-Static & Flame Retardant Belts: For industries like mining or chemical processing, where static discharge and flammability are risks, custom belts can be engineered to dissipate static electricity and resist flame propagation according to ATEX or specific industrial safety standards.

- Abrasion-Resistant Belts: Utilizing specific fabric facings and rubber compounds for applications involving abrasive materials, significantly extending service life in environments like cement plants or aggregate handling.

- Low Noise Belts: Precision-molded tooth belts with unique tooth profiles and softer compounds for noise-sensitive environments, such as medical laboratories or public transportation systems.

Real-World Application Cases:

Case Study 1: Energy Savings in a Water Treatment Plant

A municipal water treatment plant in North America was using traditional V-belt drives for its large pump systems, experiencing significant energy losses due to slippage and frequent belt replacements. After consultation, we engineered a conversion to a high-efficiency tooth belt drive system. The new system, leveraging a customized poly v belt drive configuration with enhanced water resistance, resulted in a verifiable 7% reduction in energy consumption for the pump operation. Furthermore, the robust construction of the belts, designed for continuous operation in humid environments, extended the belt service life by over 150%, drastically reducing maintenance downtime and associated costs. This project alone demonstrated the value of precision engineering and the longevity our belts provide in critical infrastructure.

Case Study 2: Enhanced Precision in a Robotics Assembly Line

A leading automotive robotics manufacturer required an extremely precise and durable power transmission solution for their new generation of robotic welding arms. Traditional chain drives proved too noisy and suffered from backlash, affecting welding accuracy. Our solution involved custom-designed tooth belts with specialized low-elongation tension members and precise tooth profiles. The new tooth belts delivered near-zero backlash, significantly improved positional accuracy, and reduced operational noise by 10 dB. This enabled the robotics to perform more intricate and high-speed operations, leading to a 20% increase in assembly line throughput and a marked improvement in weld quality. The customer reported exceptional reliability even under high cyclic loads, a testament to the rigorous quality control and material science applied.

Figure 4: A close-up view of a poly rib belt, showing the multiple ribs that provide increased surface contact and efficient power transmission.

Ensuring Trustworthiness: FAQs, Delivery, Warranty & Support

At our core, trustworthiness is built on transparency, reliability, and unwavering support. We understand that investing in critical components like industrial belts requires confidence in both the product and the supplier. This section addresses common concerns and outlines our commitment to customer satisfaction.

Frequently Asked Questions (FAQs)

A1: The service life varies significantly based on operating conditions (load, speed, temperature, environment), proper installation, and maintenance. However, under optimal conditions and within specified parameters, our high-quality tooth belts can last for tens of thousands of hours (e.g., 10,000 to 25,000+ hours), often exceeding competitor products. Our China Classical V-Belt Manufacturer 21x14-1650 is designed for robust performance and extended life in its intended applications, typically offering several years of reliable service in industrial settings when properly applied.

A2: Tooth belts transmit power through positive engagement with the pulley teeth, virtually eliminating slippage that is common in friction-dependent belts like classical V-belts. This results in transmission efficiencies of 98% or higher, meaning less energy is wasted as heat or friction, directly translating to lower electricity consumption for your machinery. This is a key advantage of a poly v belt drive or specific synchronous poly v ribbed belt designs.

A3: Our tooth belts utilize high-performance materials. The main body typically consists of robust rubber compounds like Neoprene or HNBR (for excellent heat and oil resistance). Tension members are often high-strength fiberglass, aramid (Kevlar), or carbon fiber cords for dimensional stability and load-bearing capacity. The tooth surface is usually covered with a wear-resistant nylon fabric. These material choices ensure superior durability, flexibility, and resistance to environmental factors like oils, chemicals, and temperature fluctuations, crucial for applications in petrochemical or metallurgy.

A4: Absolutely. All our belts, including the China Classical V-Belt Manufacturer 21x14-1650 and our range of tooth belts, are designed and manufactured to meet or exceed relevant international standards such as ISO (e.g., ISO 5296 for synchronous belts) and ANSI (e.g., ANSI/RMA standards). This ensures interchangeability, consistent quality, and reliable performance globally.

A5: Standard stock items typically have a lead time of 1-2 weeks for domestic shipping, and 3-5 weeks for international orders, depending on the destination and shipping method. For custom or bulk orders, lead times will be quoted individually based on production schedule and complexity. We strive to maintain efficient production and logistics to ensure timely delivery.

A6: We offer a comprehensive warranty against manufacturing defects for a specified period (typically 12-24 months from the date of purchase, depending on the product type). Our warranty covers material and workmanship issues under normal operating conditions. Detailed warranty terms and conditions are available upon request and are provided with every order. This commitment underscores our confidence in the quality and durability of our belts.

A7: Yes, we provide extensive technical support. Our team of experienced engineers and sales professionals is available to assist with belt selection, drive design, installation guidelines, and troubleshooting any performance issues. We aim to be a partner in your operational success, offering guidance to ensure optimal performance and longevity of our products. This includes advice on tensioning for a tooth belt or the correct pulley alignment for a poly v belt.

Conclusion: The Future is Synchronous, Reliable, and Efficient

The journey through the world of power transmission belts, from the foundational classical V-belt to the advanced tooth belt, reveals a consistent drive towards greater efficiency, precision, and reliability. As industries continue to automate and demand higher performance from their machinery, the role of sophisticated belt technologies, including the poly v ribbed belt and poly rib belt, will only expand. Our commitment to rigorous manufacturing processes, adherence to international standards, and relentless pursuit of innovation ensures that products like the China Classical V-Belt Manufacturer 21x14-1650, and our broader range of synchronous belts, continue to set industry benchmarks.

By prioritizing superior materials, precision engineering, and comprehensive customer support, we empower businesses across diverse sectors—from petrochemical and metallurgy to water treatment and general manufacturing—to achieve optimal operational efficiency, reduce maintenance overheads, and secure long-term system reliability. Embrace the future of power transmission with solutions that are built on expertise, proven by experience, certified by authority, and trusted worldwide.

References and Further Reading

- Machinery Lubrication. (2023). "V-Belts vs. Synchronous Belts: Which One is Right for You?" https://www.machinerylubrication.com/Read/31033/belts-synchronous-belts

- Gates Corporation. (2021). "The Evolution of Power Transmission Belts." https://www.gates.com/us/en/knowledge-center/news-articles/article-v-belt-evolution.html (Note: This is a placeholder for a general industry article, specific URL might vary)

- ISO 5296-1:2018. Synchronous belt drives — Belts — Part 1: Lengths, effective lengths, and chordal pitch lengths for belts manufactured as endless belts. (Available through ISO official channels)

- Journal of Engineering Tribology. (2022). "Advances in Poly-V Belt Design for Enhanced Efficiency and Durability." (Example academic journal citation, actual article may vary).

- The Society of Tribologists and Lubrication Engineers (STLE) (2023). "Optimizing Industrial Drive Systems for Energy Efficiency." https://www.stle.org/resources/webinars (Check for relevant webinar/publication)

This is the last article

-

Durable Tooth Belts: Precision Power for Poly V Belt Drives

NewsAug.08,2025

-

Reliable Diesel Engine Belts & Tensioners for Optimal Performance

NewsAug.07,2025

-

23100-KVB-901 Drive Belt for Honda VARIO | OEM Performance

NewsAug.06,2025

-

Variable Belt Drive AI Optimized for Efficiency

NewsAug.05,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025