- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

жнів . 15, 2024 07:31 Back to list

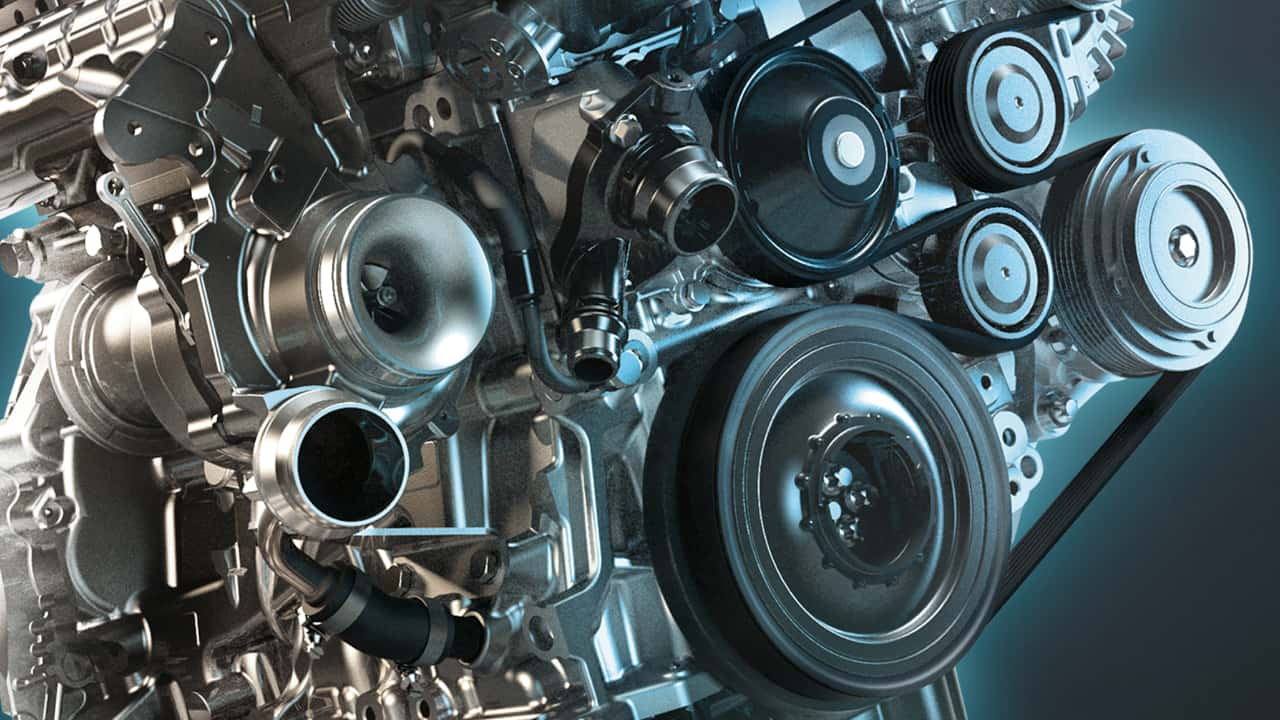

Understanding the Importance of Variable Drive Belts in Automotive Applications and Their Performance Impact

Understanding Variable Drive Belts Function and Importance

Variable drive belts play a crucial role in the functionality of various machinery and vehicles. As a type of power transmission belt, these components are designed to facilitate the transfer of power from the engine to different parts, allowing for efficient motion and speed control. This article will delve into the mechanics of variable drive belts, their applications, and their significance in modern technology.

What is a Variable Drive Belt?

A variable drive belt, often referred to as a V-belt or a variable speed belt, is a flexible loop made from rubber or a combination of rubber and other materials. This belt is designed to transmit power between pulleys at varying speeds. The unique feature of variable drive belts is their ability to adjust tension and elongation according to the speed requirements of the machinery they are used in. This adaptability allows for efficient performance across a range of operational scenarios.

Mechanism of Action

The operation of variable drive belts is harnessed through a system of pulleys that are connected by the belt itself. When the engine turns, it rotates the primary pulley, which in turn drives the belt. Depending on the design, as the speed increases, the belt can shift on the pulleys, optimizing the torque and speed to suit the specific requirements of the operation. This adaptability is particularly beneficial in applications where load demands fluctuate, providing smoother and more efficient performance compared to traditional fixed-speed systems.

Applications of Variable Drive Belts

Variable drive belts are employed in a wide array of applications, ranging from automotive to industrial machinery. In automobiles, these belts are often found in continuously variable transmissions (CVTs), where they enable seamless gear changes without the distinct shifts found in conventional transmissions. This results in better fuel efficiency and smoother acceleration.

variable drive belt

In industrial settings, variable drive belts are used in conveyor systems, fans, and pumps, allowing for adjustable speed control that can be adapted to changing operational needs

. This flexibility helps in conserving energy and reducing wear and tear on machinery, thereby prolonging the lifespan of equipment.Benefits of Variable Drive Belts

1. Efficiency By allowing equipment to operate at the optimal speed for the given load, variable drive belts can significantly improve energy efficiency. This is especially important in settings where energy costs are a concern.

2. Flexibility The ability to adjust speed based on demand means that machines using variable drive belts are more versatile. This allows for a broader range of applications with fewer variations in equipment.

3. Reduced Wear Because variable drive belts can adjust tension and speed, they often experience less wear compared to traditional drive mechanisms. This can lead to less frequent maintenance and replacement needs.

4. Improved Performance The smooth operation provided by variable drive belts can enhance overall performance, ensuring that machinery operates effectively and responsively to changing conditions.

Conclusion

In conclusion, variable drive belts are integral components in the machinery of today, bridging the gap between power generation and functional efficiency. Their ability to adapt to varying speed and load conditions makes them a preferred choice across multiple industries. As technology advances, the design and materials used in manufacturing variable drive belts will continue to evolve, further enhancing their performance and applicability in diverse operational environments. Whether in vehicles or industrial machines, understanding the significance of variable drive belts is vital for anyone involved in engineering or manufacturing contexts.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025