- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

жнів . 11, 2025 10:40 Back to list

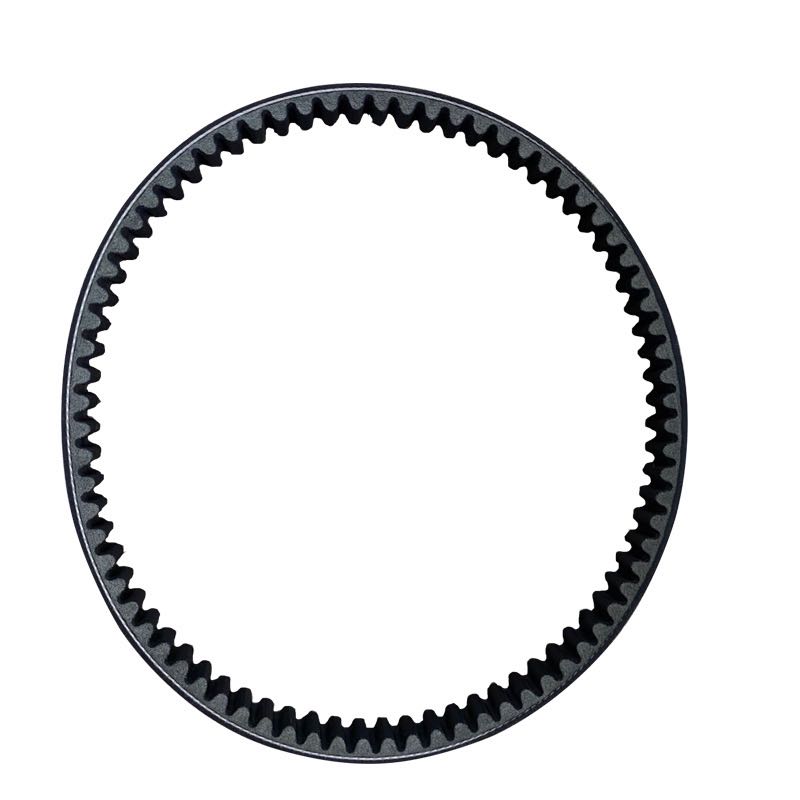

Flat Drive Belts for Sale – Durable & High Performance

The Evolving Landscape of Industrial Drive Belts: Beyond Traditional Flat Belts

In the realm of industrial power transmission, the demand for efficient, durable, and reliable drive solutions remains paramount. While the search for flat drive belts for sale persists, modern industrial applications often gravitate towards advanced alternatives like high-performance V-belts due to their superior efficiency and power transmission capabilities. Our featured product, the Generator Efficient 13X1050LA V-Belt Transmission Belts with Rubber Gear Transmission dynamo belt, exemplifies this evolution, offering optimized power transfer and longevity for critical generator and transmission systems. This article delves into the latest trends, technological advancements, and the rigorous standards that define cutting-edge drive belt solutions, ensuring you make informed procurement decisions for your operational needs.

Understanding the nuances between various belt types, from traditional flat drive belts to sophisticated V-belt designs, is crucial for optimizing machinery performance. Flat belts, historically significant, are known for their simplicity and suitability in high-speed, low-tension applications. However, contemporary industrial demands for higher torque, reduced slippage, and compact designs have accelerated the adoption of V-belts. Our focus here is to provide a comprehensive overview that covers the manufacturing excellence, application diversity, and the distinct advantages that modern drive belts bring to sectors ranging from petrochemical and metallurgy to water treatment and automotive, including specific models like v belt myvi 1.5 and v belt myvi 1.3, showcasing the broad utility of V-belt technology.

Industry Trends and the Evolution of Power Transmission Belts

The power transmission industry is experiencing a significant shift towards more energy-efficient, durable, and environmentally compliant solutions. This trend is driven by global initiatives for sustainability and the escalating costs of energy and maintenance. While the market for flat drive belts for sale remains niche for specific traditional applications, the mainstream industrial demand is for belts that offer extended service life, minimal energy loss, and resilience in harsh operating environments. Innovations in material science, particularly advanced rubber compounds and synthetic fibers, have revolutionized belt manufacturing, enabling the creation of belts that can withstand extreme temperatures, abrasive conditions, and heavy loads.

Furthermore, the integration of smart manufacturing principles and predictive maintenance technologies is influencing belt design. Modern V-belts, for instance, are designed not just for power transfer but also for quieter operation, reduced vibration, and lower heat generation, contributing to the overall efficiency and lifespan of the machinery. The legacy of products like vintage flat belt applications provides a historical context, highlighting the progress made from simple power transfer mechanisms to complex, engineered components vital for modern industrial automation. This evolution underscores a commitment to enhancing operational output while reducing the total cost of ownership for businesses.

Technical Parameters and Product Specifications

Selecting the appropriate drive belt requires a thorough understanding of its technical parameters, which dictate its suitability for specific applications. For industrial users seeking flat drive belts for sale or high-performance V-belts, key considerations include material composition, dimensional accuracy, power rating, speed compatibility, and resistance properties. Our Generator Efficient 13X1050LA V-Belt, for example, is crafted from high-grade rubber compounds reinforced with robust tension members, ensuring optimal power transmission efficiency and extended durability. Its specific dimensions (13mm top width, 1050mm effective length) are precisely engineered for efficient power transfer in generator and dynamo systems.

Below is a comparative table highlighting typical specifications for various industrial belts, including insights relevant for those evaluating flat drive belts for sale against modern V-belts. This data provides a clear technical perspective for B2B decision-makers and engineers. The parameters listed are crucial for determining compatibility with existing pulley systems and predicting performance under varying load conditions, ensuring peak operational efficiency and minimizing downtime.

| Parameter | Traditional Flat Belt | Industrial V-Belt (e.g., 13X1050LA) | Synchronous Belt (Example) |

|---|---|---|---|

| Cross-Sectional Shape | Rectangular/Flat | Trapezoidal | Toothed |

| Power Transmission Efficiency | Good (up to 98% in ideal conditions) | Excellent (95-98%, higher friction) | Excellent (98-99%, no slippage) |

| Slippage Factor | Higher, especially under variable load | Minimal, due to wedging action | None (positive engagement) |

| Space Requirement | Requires large center distances | Compact drive possible | Compact drive possible |

| Noise Level | Can be noisy if not tensioned properly | Lower, smooth operation | Higher than V-belts at high speeds |

| Typical Lifespan | Moderate (2-5 years, application dependent) | Long (3-7 years, with proper maintenance) | Very Long (5-10 years, precise applications) |

| Material Composition | Leather, fabric, rubberized fabric | Rubber (EPDM, Neoprene), Polyester cords | Polyurethane, Neoprene, fiberglass cords |

This comparison underscores why, despite the continued availability of flat drive belts for sale, V-belts have become the preferred choice for many demanding industrial and automotive applications, including specialized vehicle parts like the v belt myvi 1.5, due to their superior power density and reduced maintenance requirements. The specific design of the Generator Efficient 13X1050LA V-Belt, with its robust rubber gear transmission, is tailored for optimal grip and efficient energy transfer, minimizing power loss and enhancing the overall performance of connected machinery.

The Advanced Manufacturing Process of Drive Belts

The manufacturing of high-performance industrial drive belts, including those categorized under flat drive belts for sale and advanced V-belts, is a complex process demanding precision engineering and stringent quality control. It typically involves several critical stages, beginning with material selection and extending through fabrication, curing, and rigorous testing. This intricate process ensures that each belt meets the highest industry standards for durability, efficiency, and safety, providing a reliable component for diverse industrial applications from heavy machinery to the precise mechanics of a v belt myvi 1.3 automotive engine.

The core components include a resilient rubber compound (often EPDM or Neoprene for resistance to heat, oil, and chemicals), strong tension members (such as polyester or aramid cords for strength and dimensional stability), and a protective fabric cover (for abrasion resistance and quiet running). The manufacturing journey starts with the mixing of rubber compounds, followed by calendering to form sheets. Tension cords are then precisely aligned and embedded within these rubber sheets. For V-belts, this layered composite is then cut into raw belt shapes, which are molded and vulcanized under specific temperature and pressure conditions. This curing process cross-links the rubber polymers, giving the belt its final mechanical properties and ensuring long-term integrity.

Quality assurance is integral throughout the process. Belts undergo extensive testing for length accuracy, tensile strength, flexibility, dynamic fatigue, and resistance to environmental factors like oil and heat. Adherence to international standards such as ISO 5289 (for V-belts) and ANSI/RMA (Rubber Manufacturers Association) guidelines ensures product consistency and reliability. Our Generator Efficient 13X1050LA V-Belt Transmission Belts are produced under strict quality management systems, guaranteeing a projected service life that minimizes operational disruptions and maximizes the return on investment. This meticulous attention to detail at every stage of manufacturing ensures that our belts offer superior performance, energy efficiency, and corrosion resistance, making them ideal for demanding sectors like petrochemical processing, metallurgy, and water and wastewater treatment plants.

Diverse Application Scenarios and Technical Advantages

Modern industrial drive belts are indispensable components across a multitude of sectors, facilitating the efficient transfer of power in various machinery. While traditional flat drive belts for sale still find applications in older or specialized equipment, the robust design and superior grip of V-belts like our Generator Efficient 13X1050LA V-Belt make them ideal for high-stress and continuous operation environments. These belts are critical in industries requiring reliable power transmission, such as petrochemical plants where safety and continuous operation are paramount, or in metallurgical operations where machinery endures heavy loads and extreme conditions.

Beyond heavy industry, these versatile belts are essential in power generation (dynamo and generator drive systems), agricultural machinery, HVAC systems, and even specific automotive applications. The advantages are numerous: they include significant energy savings due to reduced slippage, enhanced resistance to harsh chemicals, oils, and high temperatures, and superior anti-corrosion properties crucial for operations in environments exposed to moisture or corrosive agents. Compared to a webbing slings flat belt used for lifting, industrial drive belts are engineered for continuous, dynamic power transfer, showcasing a completely different set of performance criteria and material specifications. Their consistent performance minimizes downtime, reduces maintenance costs, and extends the operational life of expensive industrial equipment, making them a wise investment for any B2B operation.

Manufacturer Comparison and Our Competitive Edge

When evaluating industrial drive belt suppliers, especially for essential components like those categorized under flat drive belts for sale or high-performance V-belts, distinguishing factors include manufacturing expertise, adherence to international standards, and a proven track record of reliability. Unlike general suppliers, a specialized manufacturer provides not just products, but solutions backed by deep technical knowledge and extensive experience. Our company stands out due to our relentless commitment to R&D, leveraging advanced materials and manufacturing techniques to produce belts that consistently exceed performance expectations in real-world scenarios, including heavy-duty industrial applications.

We differentiate ourselves through our unwavering focus on quality, demonstrated by our ISO 9001 certification, which underscores our rigorous quality management systems from raw material procurement to final product inspection. Our belts, including the Generator Efficient 13X1050LA V-Belt, are subjected to comprehensive fatigue tests and stress analyses to ensure maximum operational lifespan and minimal maintenance. With over two decades of experience in the power transmission industry, we have partnered with leading companies across various sectors, providing robust and reliable belt solutions. Our authoritative standing is further solidified by our consistent investment in cutting-edge production machinery and continuous training for our technical team, ensuring that every product supplied meets or exceeds global industry benchmarks, surpassing many competitors who may offer a limited range or less stringent quality controls.

Customization Solutions for Unique Industrial Demands

Recognizing that standard products, even high-quality flat drive belts for sale or V-belts, may not always suffice for highly specialized or unique industrial machinery, we offer comprehensive customization solutions. Our engineering team collaborates closely with clients to develop tailored belt specifications that precisely match the operational parameters and environmental challenges of their specific applications. This bespoke service covers variations in length, width, material composition for enhanced resistance to chemicals or extreme temperatures, and specialized coatings for improved grip or reduced friction. Whether it's for a unique production line or a highly specific piece of machinery where a conventional vintage flat belt would not perform adequately, our capabilities ensure a perfect fit and optimal performance.

The customization process begins with a detailed assessment of your requirements, followed by material selection, prototype development, and rigorous testing. This iterative approach ensures that the final product, such as a custom variant of our Generator Efficient 13X1050LA V-Belt, delivers peak performance and reliability. Our flexibility in manufacturing allows us to cater to both large-volume orders and specialized low-volume requirements, ensuring that every client, regardless of scale, receives a solution optimized for their unique operational needs. This commitment to adaptability and precision engineering underscores our dedication to solving complex power transmission challenges, providing custom-engineered belts that deliver unparalleled efficiency and longevity.

Ensuring Trust and Reliability: FAQ, Delivery, and Warranty

Building trust with our B2B clientele is fundamental to our operations. We understand that acquiring critical industrial components like flat drive belts for sale or high-performance V-belts involves significant investment and reliance. Therefore, we prioritize transparency, reliability, and robust customer support. Our commitment to trustworthiness is reflected in our comprehensive FAQ section, clear delivery schedules, and solid warranty commitments. This holistic approach ensures peace of mind for our customers, knowing they are investing in products and services that meet the highest standards of quality and support.

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of the Generator Efficient 13X1050LA V-Belt?

A: With proper installation and maintenance, our V-belts typically offer a service life of 3-7 years, significantly outperforming many traditional belts, depending on the application's operating conditions. - Q: Are your belts compliant with international standards?

A: Yes, all our industrial belts, including our featured V-belts, conform to relevant international standards such as ISO and ANSI/RMA, ensuring global compatibility and reliability. Our manufacturing processes are also ISO 9001 certified. - Q: What is your typical delivery lead time?

A: For standard products like the Generator Efficient 13X1050LA V-Belt, our typical delivery period is 2-4 weeks. Customized solutions may require additional time for design and prototyping, which will be communicated clearly during the quotation phase. - Q: What kind of warranty do you offer on your products?

A: We provide a 12-month warranty against manufacturing defects from the date of purchase. This warranty underscores our confidence in the quality and durability of our drive belts, including any specialized webbing slings flat belt types for non-power transmission applications. - Q: Do you offer technical support for installation and maintenance?

A: Absolutely. Our dedicated customer support team and technical experts are available to provide guidance on product selection, installation best practices, and maintenance tips to ensure optimal performance and longevity of your belts.

Our transparent policies on delivery and warranty, coupled with responsive customer support, solidify our reputation as a trusted partner in industrial power transmission. We are committed to ensuring that every client receives not just a product, but a complete solution that guarantees operational continuity and efficiency.

Application Cases and Proven Success

Our expertise in providing high-performance drive belts is validated by numerous successful application cases across diverse industrial settings. These real-world examples underscore the reliability and efficiency of our products, particularly for those seeking reliable flat drive belts for sale alternatives or superior V-belt solutions. One notable case involves a large-scale petrochemical facility that experienced frequent belt failures on their cooling tower fans. After consulting with our engineers, they replaced their existing belts with our specialized high-temperature resistant V-belts, similar in quality to the Generator Efficient 13X1050LA V-Belt.

The result was a dramatic reduction in unscheduled downtime, extending belt lifespan by over 200% and significantly decreasing maintenance costs. Another success story comes from a metallurgical plant, where the heavy vibration and abrasive environment led to premature wear of power transmission belts. Our reinforced V-belts were integrated into their rolling mill machinery, demonstrating exceptional resilience and maintaining stable power transmission under extreme operational loads. These cases highlight not only the robust nature of our products but also our ability to provide practical, effective solutions that address specific industrial challenges, proving our experience and the authoritativeness of our engineering solutions.

Conclusion: Powering Industry with Advanced Drive Belt Solutions

In conclusion, while the search for flat drive belts for sale continues to be a market query, the evolution of industrial power transmission undeniably points towards advanced V-belt technologies for their superior efficiency, durability, and adaptability. Products like our Generator Efficient 13X1050LA V-Belt Transmission Belts embody this progress, offering a robust and energy-efficient solution for critical industrial and generator applications. Our commitment to stringent manufacturing processes, adherence to global quality standards, and dedicated customer support ensures that our clients receive not just a product, but a reliable component that drives their operational success.

As industries continue to demand higher performance, greater energy efficiency, and reduced maintenance, partnering with a knowledgeable and experienced manufacturer becomes paramount. We are dedicated to providing cutting-edge drive belt solutions that meet the evolving needs of the modern industrial landscape, ensuring peak operational performance and contributing to long-term profitability. Choose our expertise for your next power transmission challenge, and experience the difference that quality engineering and dedicated service can make.

References

- Technical Handbook for V-Belt Drives. Mechanical Power Transmission Association (MPTA) Standards.

- ISO 5289: Industrial V-belts and V-ribbed belts — Inspection of length. International Organization for Standardization.

- Rubber Manufacturers Association (RMA) Standards for Power Transmission Belts.

- "Advanced Materials in Power Transmission Belts: A Review," Journal of Industrial Engineering and Management.

- "Energy Efficiency in Belt Drive Systems," Proceedings of the ASME International Mechanical Engineering Congress and Exposition.

This is the last article

-

Flat Drive Belts for Sale – Durable & High Performance

NewsAug.11,2025

-

Precise Timing Belt Operation: Function & FAQ Guide

NewsAug.10,2025

-

Precision Double-Sided Toothed Endless Flat Drive Belts

NewsAug.09,2025

-

Durable Tooth Belts: Precision Power for Poly V Belt Drives

NewsAug.08,2025

-

Reliable Diesel Engine Belts & Tensioners for Optimal Performance

NewsAug.07,2025

-

23100-KVB-901 Drive Belt for Honda VARIO | OEM Performance

NewsAug.06,2025