- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

أكتوبر . 15, 2024 10:47 Back to list

poly v belt types

Understanding Poly V-Belt Types

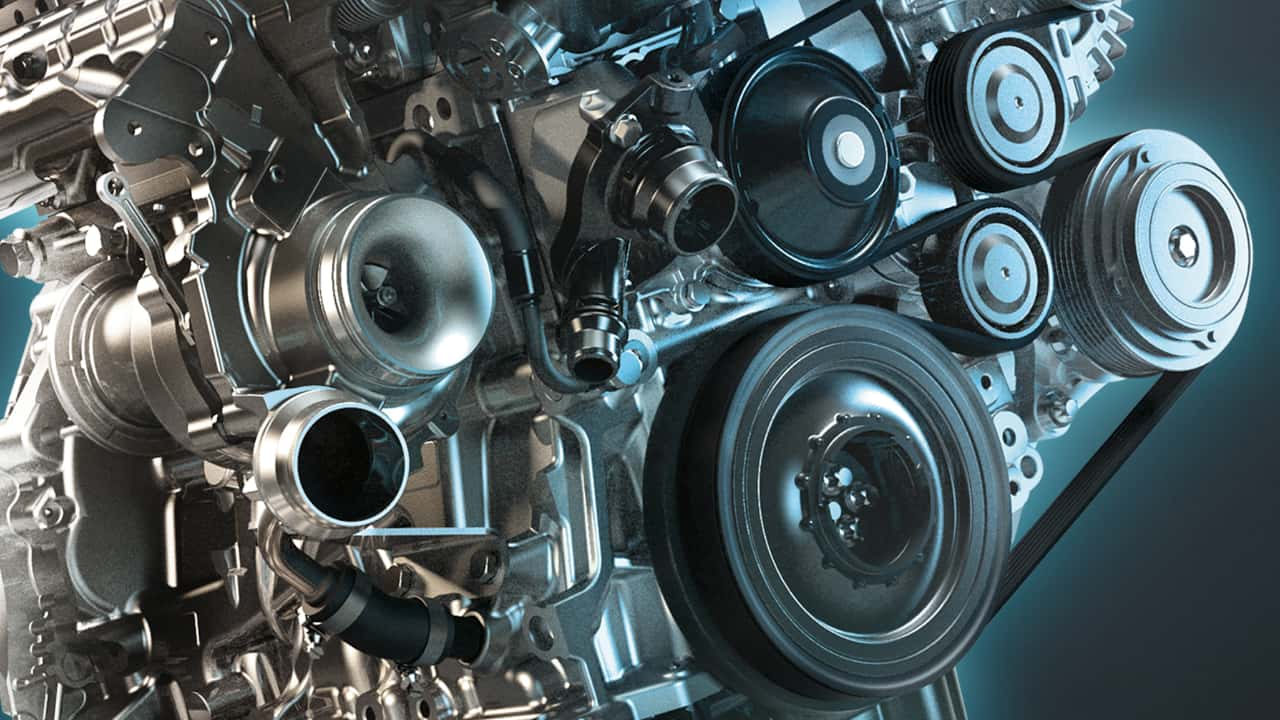

Poly V-belts, also known as ribbed belts or serpentine belts, have become increasingly popular in various applications, from automotive to industrial machinery. These belts are designed to drive multiple accessories with a single belt while maintaining high efficiency and low noise levels. Understanding the different types of Poly V-belts can help users select the best option for their specific needs.

Understanding Poly V-Belt Types

Another type of Poly V-belt is the narrow profile Poly V-belt. As the name suggests, this belt has a narrower design, which allows for a more compact installation in tight spaces. Narrow profile belts are often found in smaller engines and appliances where space is a premium. Despite their smaller size, these belts maintain excellent power transmission capabilities, making them suitable for various applications in the automotive sector and beyond.

poly v belt types

Next, we have the cogged Poly V-belt, which features notches or cogs on the back side. This design improves flexibility and allows the belt to bend more easily around pulleys, reducing the risk of wear and tear. Cogged Poly V-belts are particularly beneficial in applications that require frequent bending and twisting, such as in conveyors and material handling systems. Their enhanced flexibility also contributes to lower noise levels during operation, making them an attractive option in settings where noise reduction is essential.

In addition to these standard types, there are also specialized Poly V-belts designed for specific industries. For instance, oil-resistant Poly V-belts are manufactured with materials that withstand exposure to oils and other chemicals, making them ideal for applications in automotive or industrial environments where such substances are present. Similarly, heat-resistant Poly V-belts are designed to perform under high-temperature conditions, ensuring durability and longevity even in extreme environments.

When selecting a Poly V-belt, it is essential to consider factors such as the application, load requirements, and environmental conditions. Correctly matching the belt type to the specific needs of the system will result in enhanced performance and extended service life.

In conclusion, Poly V-belts are versatile components with various types tailored to meet diverse application needs. Whether you choose a standard, narrow profile, cogged, or specialized belt, understanding the options available will help you make an informed decision, ensuring optimal performance in your systems.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025