- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

أكتوبر . 16, 2024 17:48 Back to list

endless flat drive belt

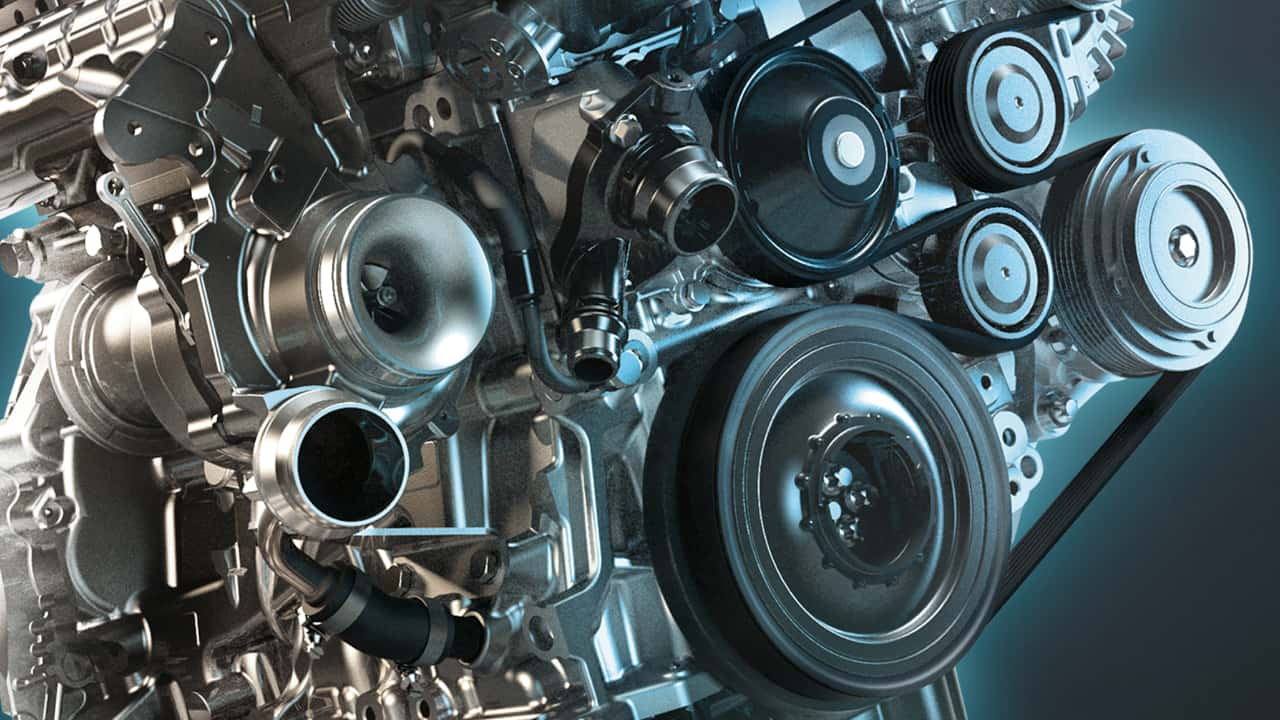

The Endless Flat Drive Belt A Comprehensive Overview

In the realm of mechanical engineering and power transmission, the endless flat drive belt has emerged as a crucial component. These belts, known for their efficiency, durability, and adaptability, have become the backbone of many industrial applications. Understanding their design, functionality, and maintenance can provide significant insights into their widespread use.

An endless flat drive belt is a continuous loop of flat material that serves to transmit power between rotating shafts. Unlike traditional V-belts or round belts, flat belts possess a rectangular cross-section. This design allows for a larger surface area in contact with pulleys, thereby enhancing grip and reducing slippage. The material composition of these belts typically includes rubber, leather, or synthetic polymers, each chosen based on specific performance requirements.

One of the primary advantages of endless flat drive belts is their ability to carry significant loads while maintaining a low profile

. In various applications, from conveyor systems to agricultural machinery, these belts can operate efficiently in confined spaces. Additionally, their flexibility allows them to navigate around pulleys and corners with ease, making them suitable for complex machinery configurations.The drive mechanism employed in flat drive belts is relatively straightforward. The belt runs over two or more pulleys, with one pulley acting as the driver and the other as the driven. The motion is transferred through friction between the belt and pulleys. To enhance this friction, many manufacturers incorporate textured surfaces on the pulleys, which improves grip and reduces the likelihood of slippage under heavy loads.

endless flat drive belt

Maintenance of endless flat drive belts is essential to ensure their longevity and optimal performance. Regular inspections for wear and tear are crucial, as any signs of fraying or damage can lead to complete failure. Proper tensioning is also vital; too loose a belt can slip, while too tight a configuration can cause premature wear on both the belt and the pulleys. Regular lubrication of the pulleys and periodic cleaning of the belt can further enhance its lifespan.

In modern engineering, the endless flat drive belt has also shown immense versatility. They are increasingly being integrated into more advanced technology, including robotics and automation. With the rise of Industry 4.0, these belts play a fundamental role in connecting various components, enabling seamless coordination in complex systems.

Moreover, as industries strive for sustainability, endless flat drive belts offer an eco-friendly alternative to other power transmission methods. Their production often utilizes recyclable materials, and their efficiency can lead to reduced energy consumption in various applications.

In conclusion, the endless flat drive belt is a remarkable innovation in the field of power transmission. Its design, functionality, and adaptability render it indispensable in numerous industrial sectors. With ongoing advancements in materials and design techniques, the future of endless flat drive belts looks promising, as they continue to evolve and meet the growing demands of modern technology.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025