- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

መስከ . 22, 2024 23:06 Back to list

moulded poly v belt

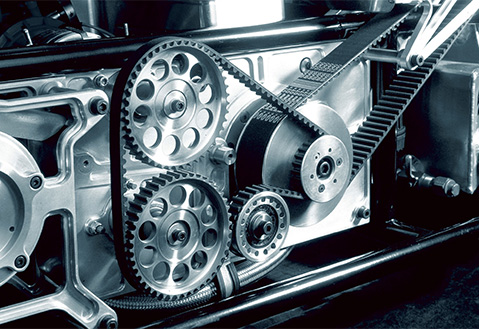

The Rise of Moulded Poly V Belts in Modern Industry

In the realm of industrial machinery and automotive applications, the demand for efficient power transmission components has led to the widespread adoption of moulded poly V belts. These belts, characterized by their unique construction and versatility, have revolutionized how machines and engines operate.

The Rise of Moulded Poly V Belts in Modern Industry

One of the primary benefits of moulded poly V belts is their ability to transmit power efficiently across a range of speeds. This adaptability makes them suitable for various applications, from automotive engines to HVAC systems and manufacturing machinery. The material composition, usually a blend of rubber and polyester, provides excellent wear resistance, ensuring a longer service life compared to conventional belts.

moulded poly v belt

Additionally, the moulded rib structure allows for smoother operation and quieter performance. As industrial standards evolve, the demand for quieter machinery has prompted manufacturers to seek solutions that reduce noise pollution. Moulded poly V belts, with their innovative design, meet these requirements while also providing exceptional durability, even under heavy loads.

Moreover, manufacturers are increasingly recognizing the importance of sustainability in their operations. Moulded poly V belts can be produced with environmentally friendly materials, contributing to a reduction in the carbon footprint associated with industrial processes. This aligns with the growing trend towards sustainable manufacturing practices, thereby appealing to a broader consumer base.

In conclusion, moulded poly V belts represent a significant advancement in power transmission technology. Their unique design, coupled with material innovations, offers enhanced performance, durability, and sustainability. As industries continue to prioritize efficiency and environmental responsibility, the adoption of moulded poly V belts is poised to grow, solidifying their place as a crucial component in modern machinery and automotive applications. Embracing these advanced solutions will not only drive performance improvements but also foster a more sustainable future for manufacturing and engineering sectors.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025