- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Okt . 04, 2024 11:19 Back to list

toothed rubber drive belts

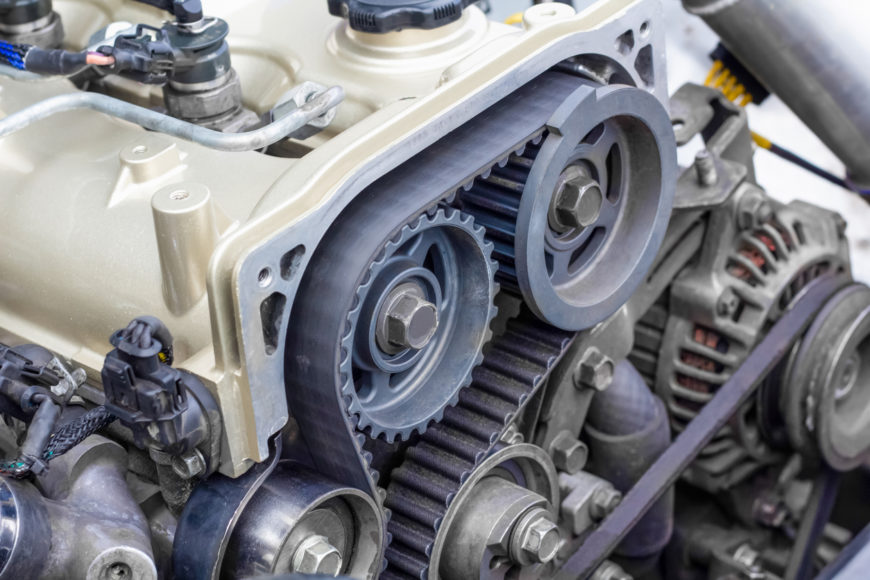

Understanding Toothed Rubber Drive Belts

Toothed rubber drive belts, also known as timing belts, play a crucial role in various mechanical systems. These belts are designed to transmit power and synchronize the rotation of components within machinery and vehicles. The unique toothed design ensures a positive engagement with pulleys, preventing slippage and maintaining precise timing between moving parts.

One of the primary benefits of toothed rubber drive belts is their efficiency. Unlike traditional flat belts, which can slip under heavy loads or high speeds, toothed belts operate with minimal slippage due to their toothed surface that meshes tightly with the corresponding sprockets. This feature allows them to maintain consistent power transmission even in dynamic conditions, making them ideal for applications in automotive engines, industrial machinery, and robotics.

Toothed rubber drive belts are typically made from a combination of rubber and reinforcing materials such as fiberglass or nylon, which enhances their strength and durability. This construction enables them to withstand high tensile forces and extreme temperatures, ensuring long service life and reliability. Additionally, the rubber composition provides flexibility, allowing the belts to navigate around pulleys without compromising efficiency.

toothed rubber drive belts

Maintenance is another critical aspect of toothed rubber drive belts

. While they are generally low-maintenance compared to chains or gears, regular inspections are essential to ensure optimal performance. Signs of wear, such as cracking, fraying, or loss of tension, can indicate that replacement is needed. Proper alignment and tensioning are vital, as improper installation can lead to premature failure.Industries ranging from automotive to manufacturing utilize toothed rubber drive belts due to their versatility and effectiveness. In vehicles, for instance, timing belts are responsible for synchronizing the crankshaft and camshaft, ensuring that valves open and close at the right times. In manufacturing, these belts drive conveyors and machinery, contributing to efficient production processes.

In conclusion, toothed rubber drive belts are an integral component in many mechanical systems, offering advantages such as efficiency, durability, and reliability. As technology continues to advance, these belts will likely play an even more significant role in enhancing the performance and longevity of machinery in various sectors. Understanding their function and maintenance is essential for anyone working with systems that rely on these crucial components.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025